220 Volts 800 Watts Metal Heating Coil Wire Elements with Nichrome Resistance Heating Wire

- Product Details

Product Description

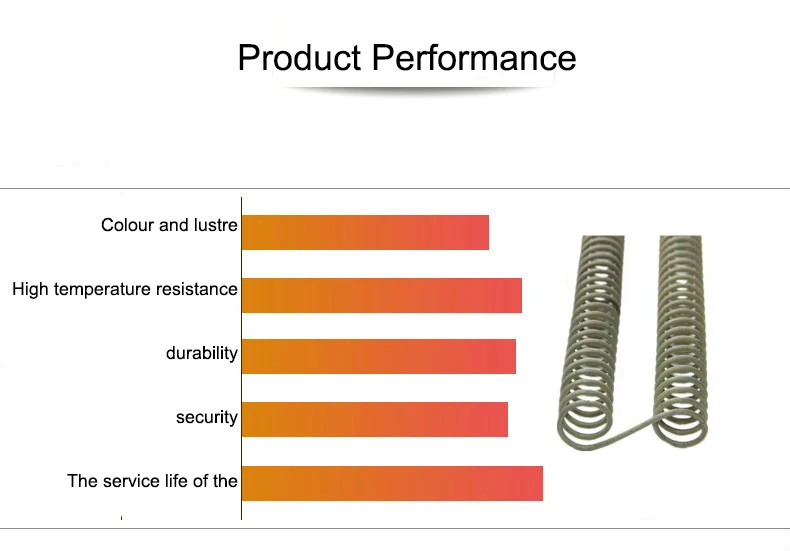

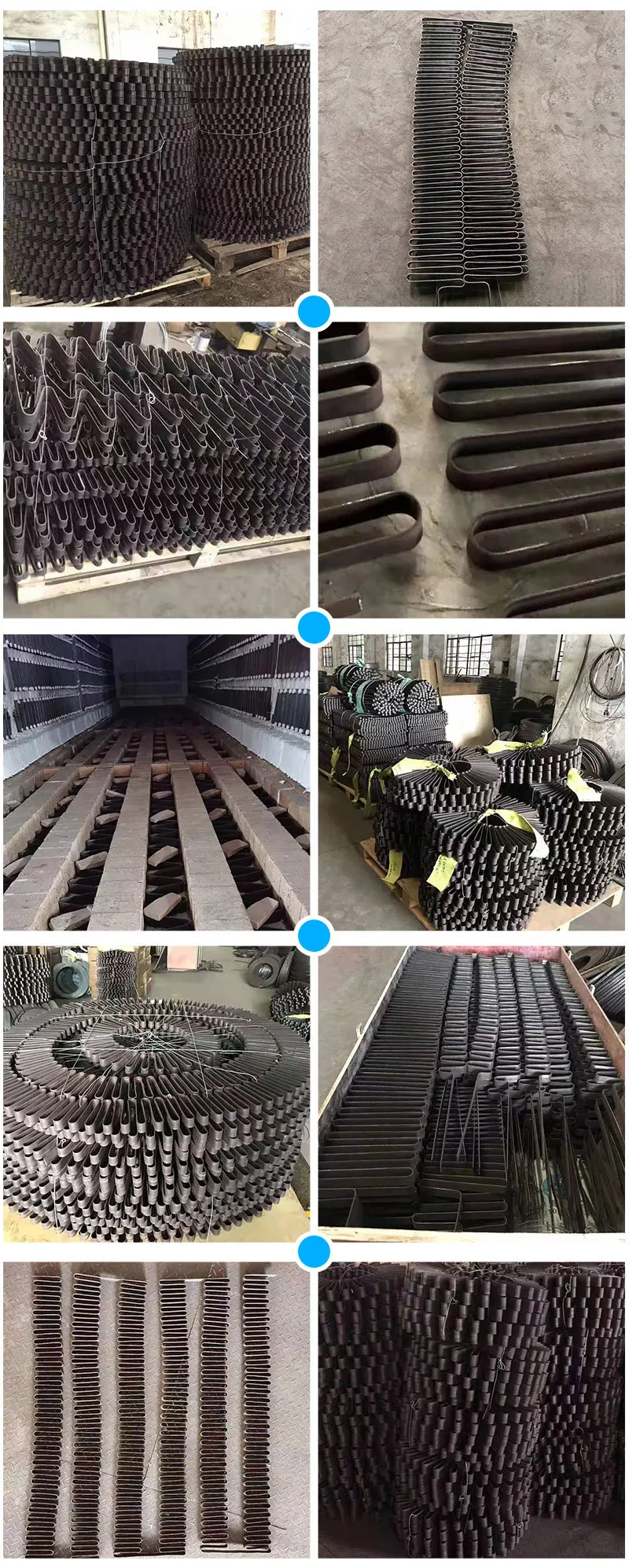

FeCrAl electric resistance alloy heating wire coil for furance

normal material of Fe-Cr-Al alloy.

FeCrAl alloy has the characteristic of high resistivity,low temperature resistance coefficient,high operating temperature,goodanti-oxidation and anti-corrosion under high temperature.

It is widely used in industrial furnace, household appliances, industry furnace, metallurgy, machinery, aircraft, automotive, military and other industries producing heating elements and resistance elements.

Alloy Nomenclature Performance | 1Cr13AL4 | 0Cr25Al5 | 0Cr21AL6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

Main Chemical composition | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

Re | opportune | opportune | opportune | opportune | opportune | opportune | opportune | |

Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

Nb0.5 | Mo1.8-2.2 | |||||||

Max. continuous service temp. of element(°C) | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

Resistivity at 20ºC(μΩ·m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

Density(g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

Thermal conductivity(KJ/m·h·ºC) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | -- | |

Coefficient of lines expansion(α×10-6/ºC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

Melting point approx.( ºC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

Tensile strength(N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

continuous service time(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥50/1350 | ≥50/1350 | |

Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Heating coil wire elements are a key component in various heating devices. They generate heat through electrical resistance and are commonly used in appliances such as toasters, ovens, and industrial heaters.

How Heating Coil Wire Elements Work

Material:

Common Materials: Heating coils are typically made from materials with high electrical resistance and good thermal conductivity, such as nichrome (nickel-chromium alloy), kanthal (iron-chromium-aluminum alloy), or stainless steel.

Properties: These materials are chosen for their ability to withstand high temperatures and resist oxidation.

Construction:

Wire Form: The heating element is usually a wire or a coiled form of the heating material. The wire is often wound into a coil or spiral to increase surface area and heat distribution.

Insulation: The heating wire is often insulated with materials like mica or ceramic to protect against electrical shorts and to ensure safe operation.

Operation:

Electric Current: When an electric current passes through the heating coil, the electrical resistance of the wire converts electrical energy into heat.

Heat Generation: The wire heats up due to the resistance and radiates heat into the surrounding area. The design of the coil, including its length and thickness, determines the heating capacity and distribution.

Heat Transfer:

Direct Heating: In devices where the coil is exposed, such as in toasters or electric stovetops, heat is transferred directly to the object being heated.

Indirect Heating: In some devices, the coil is enclosed, and heat is transferred to a heat exchanger or directly to the air through a fan or convection system.

Applications

Household Appliances:

Toasters: Heating coils toast bread by applying direct heat.

Ovens and Stoves: Coils in these appliances provide heat for cooking and baking.

Industrial Uses:

Furnaces: Heating coils are used in industrial furnaces for metal processing or other high-temperature applications.

Heat Treating: Used to achieve precise temperatures for materials processing.

Commercial Equipment:

Coffee Makers: Heating coils are used to heat water or coffee.

Hair Dryers: In hair dryers, heating coils are used to blow hot air onto the hair.

Specialty Applications:

Laboratory Equipment: Heating coils are used in laboratory devices for precise temperature control.

Medical Devices: Some medical devices use heating coils for therapeutic or diagnostic purposes.

Advantages

High Efficiency: Heating coils are efficient at converting electrical energy into heat.

Fast Heating: They can quickly reach high temperatures, making them suitable for applications requiring rapid heating.

Versatility: They can be designed in various shapes and sizes to fit different heating needs.

Considerations

Durability: Over time, heating coils can degrade due to repeated heating and cooling cycles. Proper maintenance and quality materials help extend their lifespan.

Safety: Proper insulation and design are crucial to prevent electrical hazards and ensure safe operation.

Company Profile

Over the years, we have worked hard to promote and realize the modernization of alloy sales, and actively cultivated and enhanced the ability of employees' independent innovation. All-round renovation and upgrade of the original business site, facilities and equipment, and modern computer management. Hope to establish long-term partnerships and win market reputation.

We are increasing thescale of trade and customers through out the world. With our good reputation we have won the trust of our customers. It's helps the modernisation of our country and promote the economic and technical exchanges with the rest of the world. We also look forward to enhance the friendship with other countries and make positive impact.

We warmly hope that you and us together, hand in hand, create a glorious future.

DZX alloy, which is a alloy factory more than 22 years, we are founded in 2002, and run business with resistance alloy first. And in past 20 years, we R&D new product such as Heater Emelent ,inconel, Thermocouple Series , high temperature alloy and other nickel based alloy products.

FAQ:

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal We are doing the best to match your demand.What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed. Normal order is 10-30days, it depends on customers’ quantity. Anyway,we try to offer good-quality products as soon as possible.