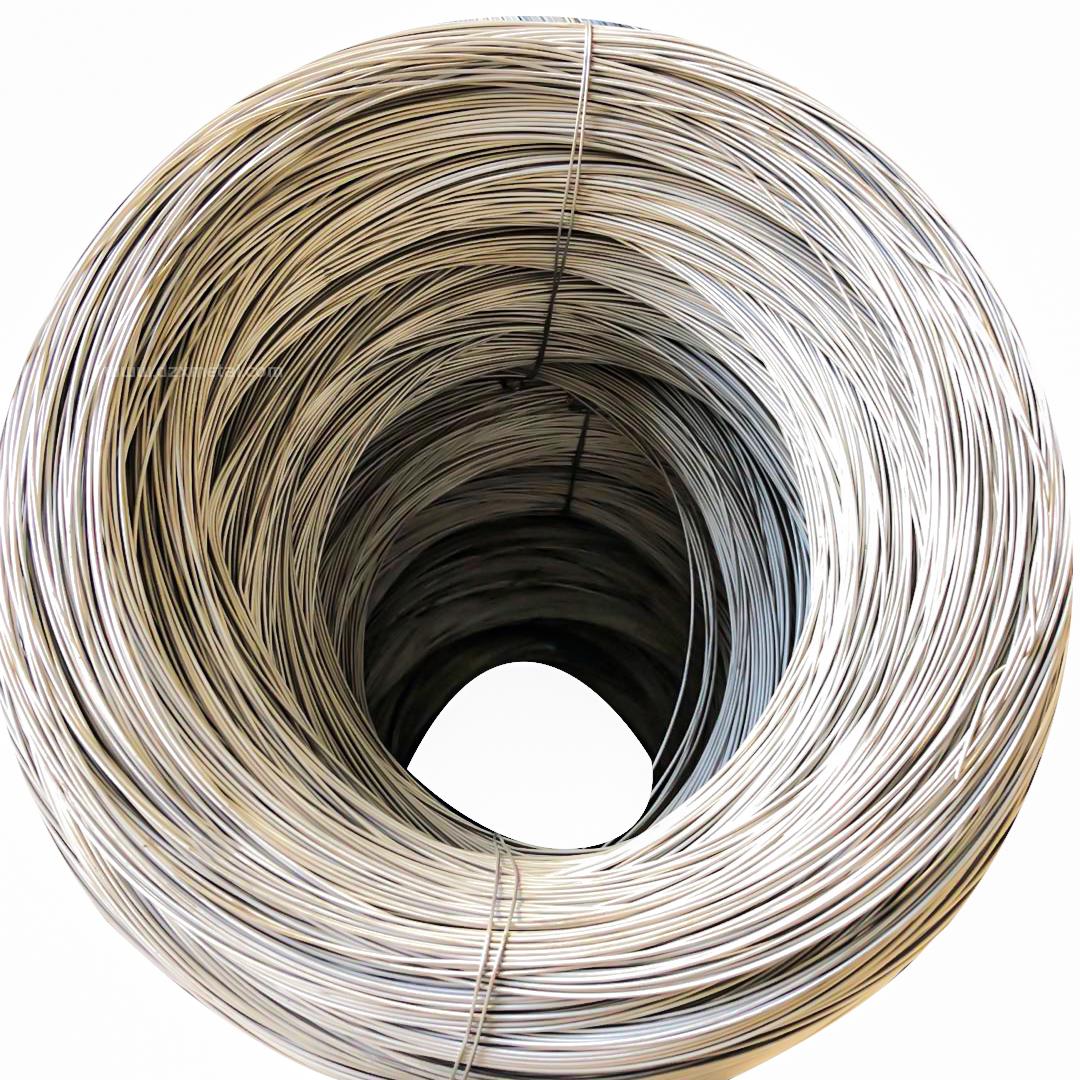

Best Price Titanium Alloy Wire Gr1 Gr2 Gr5 Gr7 Gr12 - High Strength & Anti-Corrosion

- Product Details

Product Overview

Our titanium alloy wire represents the highest standard in precision metal wire manufacturing, offering unparalleled performance characteristics for critical applications across aerospace, medical, and industrial sectors. Engineered to exacting specifications, this wire combines titanium's natural advantages with precision processing to deliver consistent, reliable performance in even the most challenging environments.

Key Features

Exceptional Material Properties

High strength-to-weight ratio: Superior to steel wire of comparable diameter

Outstanding corrosion resistance: Excellent performance in saltwater, chemical, and acidic environments

Biocompatibility: Ideal for medical implants and surgical applications

Fatigue resistance: Maintains integrity under cyclic loading conditions

Non-magnetic properties: Essential for sensitive electronic and medical applications

Precision Manufacturing

Diameter range: 0.05mm to 6.0mm (±0.001mm tolerance for precision grades)

Surface finish options: Bright polished, acid cleaned, or oxide finish

Tensile strength options: Soft annealed to full hard temper available

Spool sizes: Standard 1kg to 20kg spools, custom packaging available

Available Alloy Grades

Grade 1 (CP Titanium): Maximum formability and corrosion resistance

Grade 2 (CP Titanium): Balanced strength and corrosion resistance

Grade 5 (Ti-6Al-4V): High strength aerospace grade

Grade 23 (Ti-6Al-4V ELI): Medical grade for implant applications

Grade 9 (Ti-3Al-2.5V): Superior cold working characteristics

Technical Specifications

| Parameter | Grade 1 | Grade 2 | Grade 5 | Grade 23 |

|---|---|---|---|---|

| Tensile Strength | 240-370 MPa | 345-480 MPa | 895-1034 MPa | 860-965 MPa |

| Yield Strength | 170-300 MPa | 275-380 MPa | 825-930 MPa | 795-875 MPa |

| Elongation | 24% min | 20% min | 10% min | 12% min |

| Density | 4.51 g/cm³ | 4.51 g/cm³ | 4.43 g/cm³ | 4.43 g/cm³ |

| Resistivity | 0.55 µΩ·m | 0.55 µΩ·m | 1.78 µΩ·m | 1.78 µΩ·m |

Scientific Principles

Titanium Wire performance is governed by:

Crystal Structure: Hexagonal close-packed (α phase) at room temperature

Alloying Effects: Aluminum increases strength, vanadium improves workability

Surface Oxide Layer: Self-healing TiO₂ layer provides corrosion resistance

Cold Work Effects: Strain hardening increases strength but reduces ductility

Annealing Response: Heat treatment can optimize strength/ductility balance

Applications

Medical Applications

Orthopedic fixation wires

Surgical suture wire

Dental arch wires

Implantable medical devices

Guide wires for catheters

Aerospace Uses

Lock wire for fasteners

Electrical bonding wire

Mesh for composite reinforcement

Repair welding wire

Instrumentation components

Industrial Applications

Chemical processing equipment

Marine hardware fasteners

Specialty springs

Welding and additive manufacturing

Jewelry and high-end consumer products

Competitive Advantages

Performance Benefits

40% lighter than steel wire with comparable strength

Superior corrosion resistance compared to stainless steel

Excellent fatigue life for dynamic applications

Biocompatible options for medical use

Non-sparking characteristics for hazardous environments

Manufacturing Advantages

Precision diameter control (±0.001mm)

Multiple temper options from dead soft to spring temper

Custom surface finishes available

Consistent quality through entire production run

Traceability from raw material to finished product

Quality Assurance

Full material certification

Dimensional inspection reports

Surface quality verification

Mechanical testing documentation

Compliance with ASTM F67, ASTM F136, AMS 4951

FAQ Section

Q: What is the minimum order quantity for titanium wire?

A: Our standard MOQ is 1kg, with discounts available for orders over 10kg.

Q: Can you supply wire with special surface finishes?

A: Yes, we offer bright polished, etched, sandblasted, and passivated finishes.

Q: What certifications do you provide with medical grade wire?

A: Grade 23 ELI wire includes full traceability and meets ASTM F136, ISO 5832-3.

Q: How does titanium wire compare to stainless steel wire?

A: Titanium offers better strength-to-weight, superior corrosion resistance, and biocompatibility.

Q: What are your packaging options?

A: Standard plastic spools, wooden reels, or custom packaging to prevent tangling.

Q: Can you supply straightened and cut lengths?

A: Yes, we offer precision-cut lengths from 100mm to 3m with straightness tolerance.

Q: What are the machining recommendations for titanium wire?

A: Use sharp carbide tools, moderate speeds, and abundant coolant for best results.

Q: Do you offer different tempers of wire?

A: Yes, from dead soft (annealed) to full hard (cold worked) temper options.

Q: Can you provide wire with specific mechanical properties?

A: We can customize tensile strength and elongation within alloy capabilities.

Q: What is your lead time for custom orders?

A: Standard grades ship in 2-3 weeks; custom orders typically 4-6 weeks.

Why Choose Our Titanium Wire?

Specialized titanium wire manufacturer with decades of experience

Complete in-house processing from melting to final drawing

Advanced quality control including laser measurement

Technical support from materials engineers

Global distribution network for reliable delivery

Ordering Information

Contact our sales team for:

Volume pricing

Custom alloys and sizes

Special testing requirements

Just-in-time delivery programs

Technical consultation

TIG Welding Titanium Filler Wire, ERTi-7 (Ti-0.2Pd), 1.6mm-4.0mm Dia, AWS A5.16 Certified

Bright Polished Titanium Wire, Grade 1, 0.3mm-1.5mm Dia, Ultra-Flexible, Craft & Electronics Applica

Ti-6Al-4V Alloy Wire (Grade 5), 1.0mm-5.0mm Dia, Cold Drawn, High Tensile Strength for 3D Printing

ASTM B863 ERTi-2 Titanium Wire, 0.1mm-3.0mm Diameter, Grade 2 Pure Ti, Annealed, for Welding & Jewel