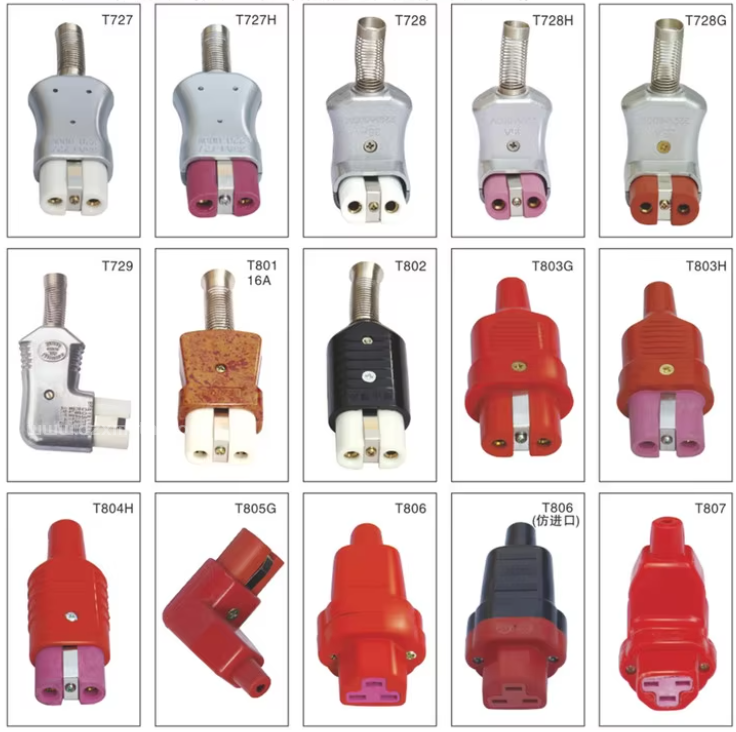

High Temperature Electric Ceramic Plug M5 M6 Hole Connector Electric Plug for Band Heater

- Product Details

Electric Ceramic Plug

An electric ceramic plug for a band heater is used to connect and power the heating element of the band heater

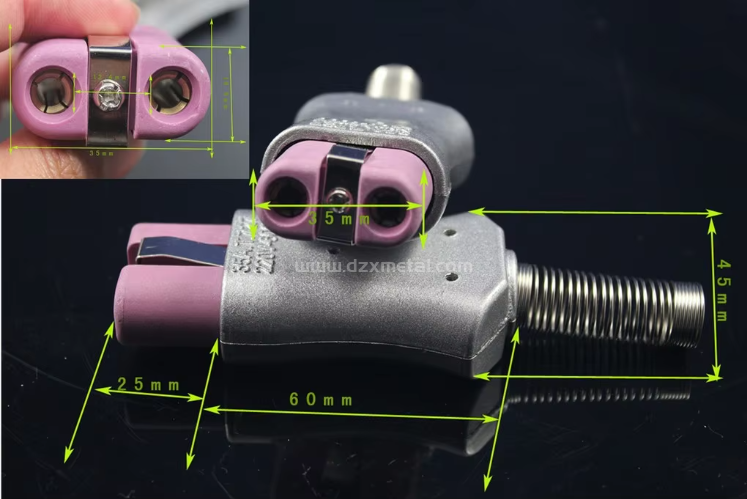

1. Silicone rubber shell high temperature resistance, 200C below, high pressure resistance (220V~600V), soft 25A-35A fluorine rubber joint resistance Acid, alkali resistance, crushing resistance jack specifications $5, $6mm, quality assurance, long service life.

2. Special high temperature resistance and high strength aluminum alloy shell imported from foreign data, high temperature resistance, 500~C, high pressure resistance (220V- -600V);

Long service life, insert each hole specification 4,5, 6mm.

Features:

Scope of application: Widely used in plastic machinery, food machinery, chemical industry and other industries and a variety of high temperature power plug connection.

High strength alloy shell, imported standard, high temperature resistance, high pressure resistance, (20 0 V-60 0 V),

Product quality is good, long service life, jack specifications are 4MM, 5MM, 6MM.

Silicone rubber housing high pressure resistance, heat resistance, soft. 25 A fluorine rubber plug, temperature resistance,

pressure resistance, acid resistance, alkali resistance Broken. (with three-eyed flat plug)

Process: High temperature plug is made of copper core contact surface and ceramic combination, in the outer metal aluminum protective shell or silicone rubber protective shell Make it.

Purpose: High temperature working environment.

Features: Can be in 500°C below the working environment as a conductor

Material: | aluminum alloy, ceramic or silicone rubber |

Temperature: | 500℃ |

Provide processing customization | yes |

Voltage | 220V-600V |

Main use: | electric furnace heating, Ceramic heater |

Product certification: | ISO9001, CE |

Function

Connection: It provides a secure electrical connection between the band heater's heating element and the power source.

Insulation: The ceramic plug insulates the electrical connections to prevent short circuits and electrical faults. Ceramic materials are chosen for their high resistance to heat and electrical conductivity.

Heat Resistance: It withstands high temperatures generated by the band heater, ensuring reliable operation even under intense heat conditions.

Components

Ceramic Insulator: Made from heat-resistant ceramic materials that prevent electrical contact from causing short circuits or overheating.

Electrical Contacts: Metal contacts inside the plug connect to the band heater's electrical terminals, allowing the current to flow from the power source.

Housing: The outer part of the plug, often ceramic, encases the internal components and provides mechanical protection.

Applications

Industrial Band Heaters: Used in machinery to heat cylindrical objects or processes requiring precise temperature control.

Plastic Molding: In manufacturing, band heaters often warm up molds or components, and the ceramic plug ensures stable electrical connections.

Advantages

Durability: Ceramic materials are highly durable and can handle high temperatures without degrading.

Safety: Provides insulation to prevent electrical accidents and overheating.

Reliability: Ensures stable and continuous operation of the band heater.

Over the years, we have worked hard to promote and realize the modernization of alloy sales, and actively cultivated and enhanced the ability of employees' independent innovation. All-round renovation and upgrade of the original business site, facilities and equipment, and modern computer management. Hope to establish long-term partnerships and win market reputation.

We are increasing thescale of trade and customers through out the world. With our good reputation we have won the trust of our customers. It's helps the modernisation of our country and promote the economic and technical exchanges with the rest of the world. We also look forward to enhance the friendship with other countries and make positive impact.

We warmly hope that you and us together, hand in hand, create a glorious future.

DZX TECH, which is a factory for heating elements more than 22 years, we are founded in 2002, and run business with resistance alloy first. And in past 20 years, we R&D new product such as Heater Emelent , air heating and water heater elements and other alloy products.

FAQ

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.