Hot Sale Grade 2 Titanium Plate - ASTM B265 Certified Sheet Metal Price Per Kg

- Product Details

Product Overview

Our titanium alloy sheets and plates represent the gold standard in high-performance metal plate products, offering an unmatched combination of strength, corrosion resistance, and lightweight properties. Precision-manufactured to meet the most stringent international standards, these plates serve critical applications across aerospace, marine, chemical processing, and medical industries where material performance cannot be compromised.

Key Features & Benefits

Exceptional Material Properties

Superior strength-to-weight ratio: 45% lighter than steel with comparable strength

Unparalleled corrosion resistance: Excellent performance in seawater, acidic, and alkaline environments

Biocompatibility: Medical-grade options available for implants and surgical applications

High temperature tolerance: Maintains structural integrity up to 600°C (1112°F)

Non-magnetic characteristics: Essential for sensitive electronic and scientific equipment

Precision Manufacturing Specifications

Thickness range: 0.5mm to 150mm (±0.02mm tolerance for precision grades)

Standard sizes: 1000mm × 2000mm, 1220mm × 2440mm, custom sizes available

Surface finishes: Mill finish, polished (up to #8 mirror), sandblasted, or embossed

Flatness tolerance: ≤0.1% of length for precision plates

Available Alloy Grades

Grade 1 (CP Titanium): Maximum formability and corrosion resistance

Grade 2 (CP Titanium): Balanced properties for general applications

Grade 5 (Ti-6Al-4V): High-strength aerospace grade

Grade 7 (Ti-0.2Pd): Enhanced corrosion resistance

Grade 9 (Ti-3Al-2.5V): Improved cold working characteristics

Grade 23 (Ti-6Al-4V ELI): Medical implant grade

Technical Specifications

Parameter | Grade 1 | Grade 2 | Grade 5 | Grade 23 |

|---|---|---|---|---|

Tensile Strength | 240-370 MPa | 345-480 MPa | 895-1034 MPa | 860-965 MPa |

Yield Strength | 170-300 MPa | 275-380 MPa | 825-930 MPa | 795-875 MPa |

Elongation | 24% min | 20% min | 10% min | 12% min |

Density | 4.51 g/cm³ | 4.51 g/cm³ | 4.43 g/cm³ | 4.43 g/cm³ |

Thermal Conductivity | 17 W/m·K | 17 W/m·K | 7.2 W/m·K | 7.2 W/m·K |

Manufacturing Process & Metallurgical Principles

Advanced Production Technology

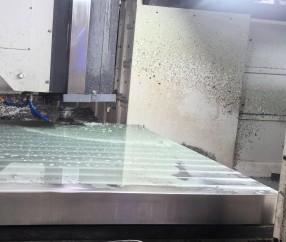

Hot Rolling Process:

Breakdown rolling of ingots at 900-1000°C

Controlled cooling for optimal microstructure

Intermediate annealing for stress relief

Cold Rolling Process:

Precision thickness reduction at room temperature

Multiple passes with intermediate annealing

Final surface treatment and finishing

Surface Treatment Options:

Electrolytic polishing for mirror finishes

Passivation for enhanced corrosion resistance

Shot peening for improved fatigue resistance

Material Science Fundamentals

Phase transformation: Alpha-beta phase balance control

Grain structure refinement: Through thermo-mechanical processing

Texture control: For improved forming characteristics

Surface integrity management: Critical for corrosion performance

Applications

Aerospace & Defense

Aircraft skin and structural components

Missile and rocket housings

Satellite shielding

Engine firewalls

Medical & Healthcare

Surgical implant components

Medical equipment housings

MRI machine components

Dental surgical guides

Industrial & Chemical Processing

Heat exchanger plates

Electrolysis cells

Chemical reactor linings

Desalination plant components

Marine & Offshore

Submarine hull components

Offshore platform structures

Ship bulkheads

Desalination equipment

Specialty Applications

Architectural cladding

Luxury watch cases

High-end automotive components

Chemical processing equipment

Competitive Advantages

Performance Benefits

45% weight reduction compared to steel plates

Zero maintenance corrosion resistance

Superior fatigue life for dynamic applications

Excellent cryogenic performance down to -250°C

Biocompatible options for medical applications

Quality Assurance

Full material traceability from ingot to final product

Ultrasonic testing for internal defects

Eddy current testing for surface flaws

Mechanical testing certification

Compliance with ASTM B265, AMS 4911, ISO 5832-2

Customization Capabilities

Special thickness and size combinations

Custom surface treatments

Precision cutting services

Proprietary alloy modifications

Laser marking and product identification

FAQ Section

Q: What is your contact information?

Q: What is your standard lead time for Titanium plate s?

A: Standard products ship within 4-5 weeks; custom orders require 6-8 weeks production time.

Q: Can you supply plates with special surface finishes?

A: Yes, we offer #4 brushed finish, #8 mirror polish, embossed, and passivated surfaces.

Q: What certifications do your medical-grade plates include?

A: Our Grade 23 plates come with full traceability and meet ASTM F136, ISO 5832-3 standards.

Q: How does titanium plate pricing compare to stainless steel?

A: While initial cost is higher, titanium's longevity and zero maintenance often provide better lifetime value.

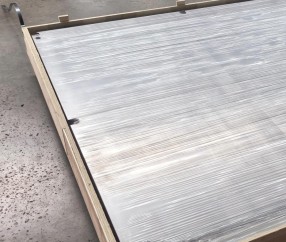

Q: What packaging standards do you use?

A: We use protective film, edge guards, and wooden crates for optimal protection during shipping.

Q: Can you supply extra-wide titanium plates?

A: Yes, we can manufacture plates up to 3000mm wide depending on thickness requirements.

Q: Do you offer stress-relieved or annealed plates?

A: Yes, we provide various heat treatment conditions to meet your specific requirements.

Q: What forming methods work best with your plates?

A: Titanium plates can be cold formed (for simple shapes) or hot formed (for complex geometries).

Q: Can you supply perforated or patterned plates?

A: Yes, we offer custom perforation and embossing services for specialty applications.

Q: Do you provide material test reports with shipments?

A: Yes, each order includes full chemical analysis and mechanical property certification.

Why Choose Our Titanium Plates?

40+ years of specialized titanium manufacturing expertise

State-of-the-art rolling mills with precision thickness control

Complete quality assurance from raw material to finished product

Technical support from materials engineering specialists

Global logistics network ensuring reliable delivery

Ordering & Customer Support

Our technical sales team provides:

Material selection guidance

Application-specific recommendations

Custom fabrication consulting

Volume pricing structures

Just-in-time inventory programs