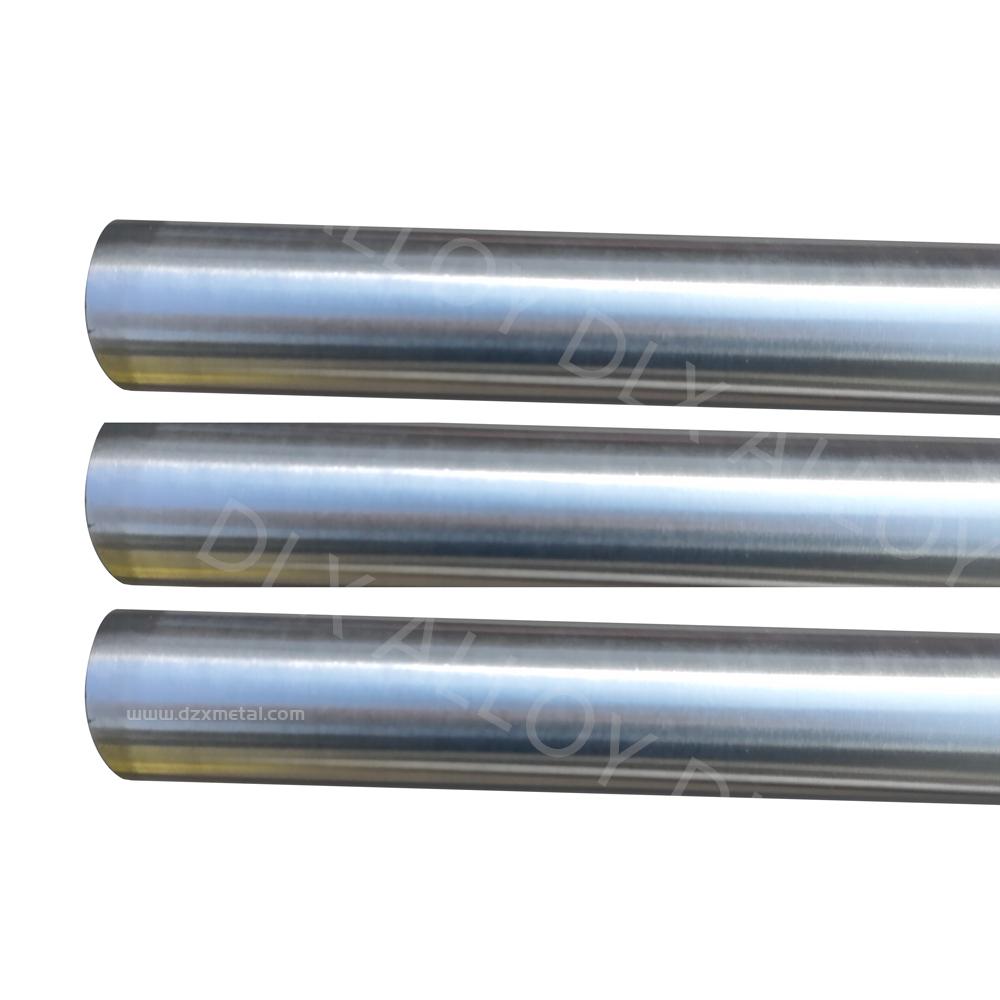

Titanium Alloy Round Bars - OEM Sizes Available, Hot-Forged & Cold-Drawn

- Product Details

Product Overview

Our premium titanium alloy rods represent the pinnacle of modern metallurgical engineering, offering an exceptional combination of strength, lightness and corrosion resistance. Manufactured to the most stringent international standards, these rods are the material of choice for aerospace, medical, and high-tech industrial applications where performance cannot be compromised.

Key Features

Superior Material Properties

High Strength-to-Weight Ratio: 40% lighter than steel with comparable strength

Exceptional Corrosion Resistance: Excellent resistance to saltwater, acids and industrial chemicals

Biocompatibility: Ideal for medical implants and surgical instruments

High Temperature Performance: Maintains structural integrity up to 600°C (1112°F)

Precision Engineering

Diameter range: 5mm to 300mm (±0.05mm tolerance)

Length: Standard 3m, custom lengths up to 6m available

Surface finishes: Polished, ground, or as-forged

Straightness tolerance: ≤0.1mm per 300mm

Material Grades Available

Grade 5 (Ti-6Al-4V): The most widely used titanium alloy

Grade 2 (Commercially Pure): Maximum corrosion resistance

Grade 9 (Ti-3Al-2.5V): Superior cold forming characteristics

Grade 23 (Ti-6Al-4V ELI): Medical grade for implants

Technical Specifications

| Parameter | Grade 5 (Ti-6Al-4V) | Grade 2 (CP) | Grade 23 (ELI) |

|---|---|---|---|

| Tensile Strength | 895-930 MPa | 345 MPa | 860 MPa |

| Yield Strength | 825-869 MPa | 275 MPa | 795 MPa |

| Elongation | 10% | 20% | 15% |

| Density | 4.43 g/cm³ | 4.51 g/cm³ | 4.43 g/cm³ |

| Melting Point | 1604-1660°C | 1668°C | 1604-1660°C |

Scientific Principles

Titanium alloys derive their exceptional properties from:

Crystal Structure: Hexagonal close-packed (α phase) at room temperature transforms to body-centered cubic (β phase) at 882°C

Alloying Elements: Aluminum stabilizes α phase, vanadium stabilizes β phase

Passive Oxide Layer: Forms instant TiO₂ surface layer preventing further corrosion

Interstitial Elements: Controlled oxygen and nitrogen content enhances strength

Applications

Aerospace Industry

Aircraft structural components

Jet engine compressor blades

Spacecraft fuel tanks

Landing gear components

Medical Field

Orthopedic implants (hips, knees)

Dental implants and prosthetics

Surgical instruments

Pacemaker cases

Industrial Uses

Chemical processing equipment

Marine hardware and shipbuilding

Power generation components

High-performance automotive parts

Competitive Advantages

Performance Benefits

45% lighter than steel with comparable strength

50% stronger than aluminum alloys

Zero corrosion in most environments

Non-magnetic properties for specialized applications

Economic Advantages

Longer service life reduces replacement costs

Lower maintenance requirements

Energy efficient machining compared to superalloys

100% recyclable material

Quality Assurance

Full material traceability

Mill test certificates included

Ultrasonic testing available

Compliance with ASTM, AMS, ISO, and EN standards

FAQ Section

Q: What is your contact information?

A: Mobile/whatsapp/skype/wechat:+8619906119641

Q: What is the lead time for custom orders?

A: Standard products ship in 2-3 weeks. Custom diameters/lengths require 4-6 weeks.

Q: Can you provide rods with special surface finishes?

A: Yes, we offer polished, sandblasted, anodized, and passivated finishes.

Q: What certifications do your products have?

A: We're ISO 9001:2015 certified and comply with ASTM B348, AMS 4928, and ISO 5832-3.

Q: How does titanium compare to stainless steel?

A: Titanium is 45% lighter, more corrosion resistant, and has better fatigue strength.

Q: What machining recommendations do you have?

A: Use carbide tools, lower speeds than steel, abundant coolant, and sharp tooling.

Q: Can you supply medical-grade certified rods?

A: Yes, we provide Grade 23 ELI with full biocompatibility certification.

Q: What packaging options are available?

A: Standard PVC wrapping, wooden crates for long rods, or custom packaging per request.

Q: Do you offer metallurgical analysis reports?

A: Yes, we provide full chemical composition and mechanical property reports.

Why Choose Our Titanium Alloy Rods?

30+ years of titanium manufacturing expertise

State-of-the-art production facilities

Custom alloy formulations available

Global logistics network for reliable delivery

Technical support from material scientists

Ordering Information

Contact our sales team for:

Volume discounts

Custom sizes and alloys

Special testing requirements

Just-in-time delivery programs