Vacuum-Compatible Titanium Alloy Substrate for Electronics & Sputtering

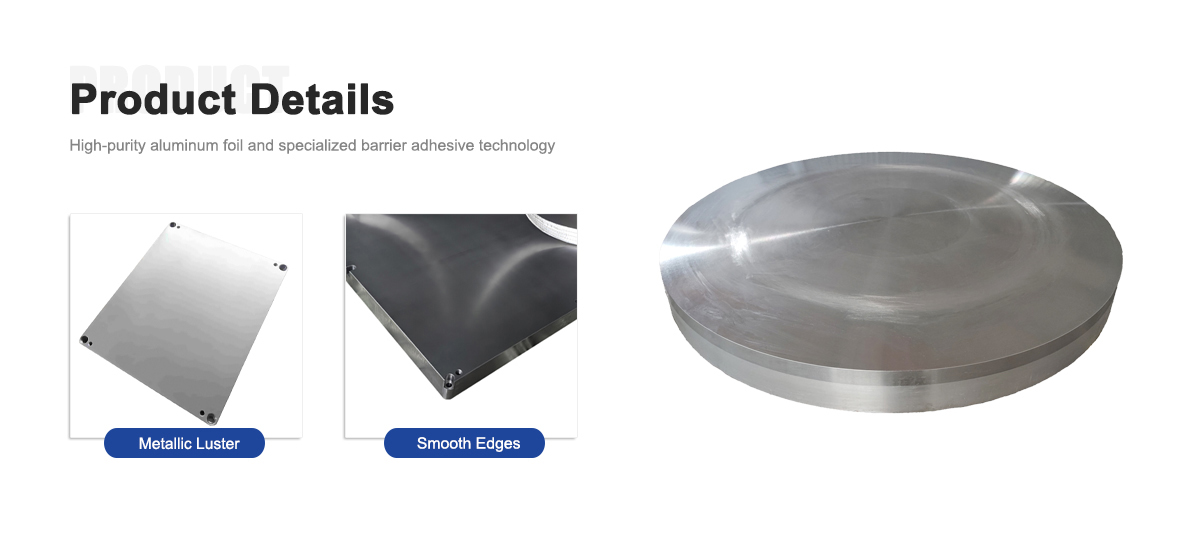

- Product Details

Description of Titanium Alloy Substrate

What is Titanium Alloy Substrate?

DZX offers a premium, high-purity titanium alloy substrate solution engineered for the most challenging technical environments. Our vacuum-compatible titanium alloy substrate is specifically designed for applications in advanced electronics, thin-film deposition, and as a robust base for sputtering targets.

This titanium alloy substrate delivers an exceptional combination of high specific strength, excellent corrosion resistance, and outstanding thermal stability. Its low outgassing properties and ultra-high vacuum (UHV) compatibility make it the material of choice for sensitive electronic manufacturing and coating processes.

Characteristics of Titanium Alloy Substrate

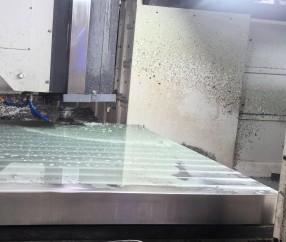

Our vacuum-compatible titanium substrate is manufactured to the highest standards, ensuring reliability and performance for your critical applications.

Superior Vacuum Compatibility: This titanium alloy substrate exhibits extremely low outgassing rates, making it ideal for UHV (Ultra-High Vacuum) environments essential in sputtering systems and high-precision electronics fabrication.

Excellent Thermal & Mechanical Stability: The titanium substrate maintains dimensional stability and mechanical integrity under high thermal loads, preventing deformation during high-temperature processing.

High Purity & Low Contamination: We provide high-purity titanium alloy substrates to minimize the risk of contamination in your thin films and electronic components, ensuring consistent and reliable results.

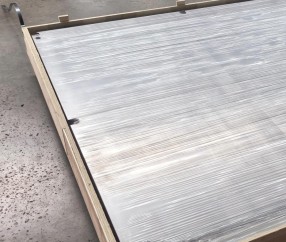

Optimized for Sputtering Target Bonding: The surface finish and flatness of our titanium alloy substrate are meticulously controlled to ensure perfect bonding with various sputtering target materials, enhancing performance and lifespan.

Outstanding Corrosion Resistance: Resistant to a wide range of corrosive environments, this substrate offers long-term durability and reliability.

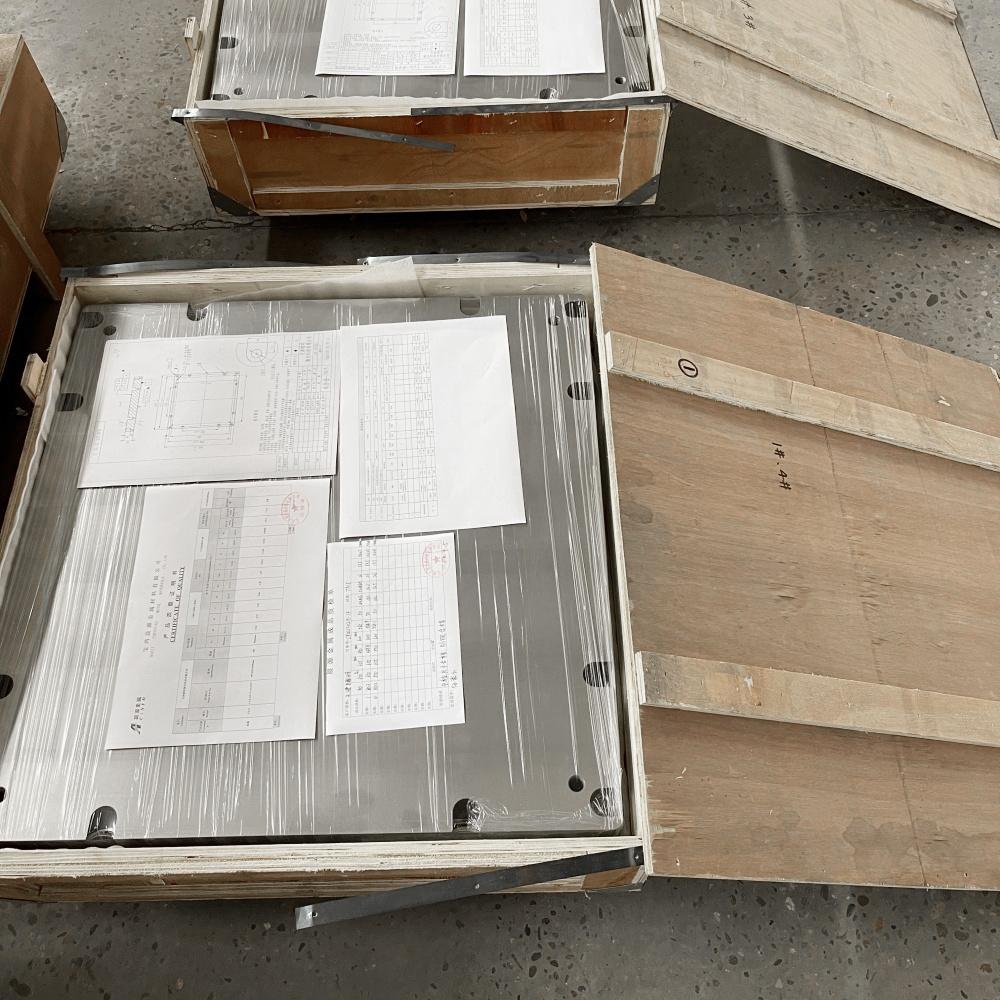

Our Titanium Alloy Substrate is manufactured to the highest industry standards, ensuring a reliable titanium base for your most critical projects.

High Strength-to-Weight Ratio

Outstanding Corrosion Resistance

Excellent Fatigue Performance

Superior Biocompatibility for Medical Implants

High-Temperature Capability & Thermal Stability

Optimized Surface for Additive Manufacturing (3D Printing)

Consistent Quality and Dimensional Accuracy

Application Field of Titanium Alloy Substrate

The unique properties of our Titanium Alloy Substrate make it a versatile solution across multiple advanced industries.

Aerospace Components:

Used in airframe structures, engine components, landing gear parts, and satellite systems where lightweight strength is non-negotiable.

Additive Manufacturing / 3D Printing:

Serves as the essential build plate and base material for producing complex, high-value aerospace components and custom medical implants using Direct Energy Deposition (DED) and other AM processes.

Medical Device Manufacturing:

The substrate of choice for permanent medical implants such as orthopedic joints, dental implants, and bone plates due to its strength and biocompatibility.

Chemical Processing:

Used in heat exchangers, reactor vessels, and piping systems that handle corrosive media.

Marine & Offshore Engineering:

Ideal for components exposed to harsh seawater environments.

Advantage of Titanium Alloy Substrate

About DZX

Jiangsu DZX Technology Co,Ltd. is a professional engaged in the electric heater design, manufacture and sales of integrated entity enterprise, has over 20 years experience in electric heater of scientific research and production.

Enterprise has core technology advantage and introduce advanced technology and management concept, in accordance with the 1s09001 quality management requirements, strict control of raw materials quality,perfect detection means, with first-class technology,reliable quality and excellent service to win customers praise and praise.

Over the years, we have worked hard to promote and realize the modernization of alloy sales, and actively cultivated and enhanced the ability of employees' independent innovation. All-round renovation and upgrade of the original business site, facilities and equipment, and modern computer management. Hope to establish long-term partnerships and win market reputation.

We are increasing thescale of trade and customers through out the world. With our good reputation we have won the trust of our customers. It's helps the modernisation of our country and promote the economic and technical exchanges with the rest of the world. We also look forward to enhance the friendship with other countries and make positive impact.

We warmly hope that you and us together, hand in hand, create a glorious future.

FAQ

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.