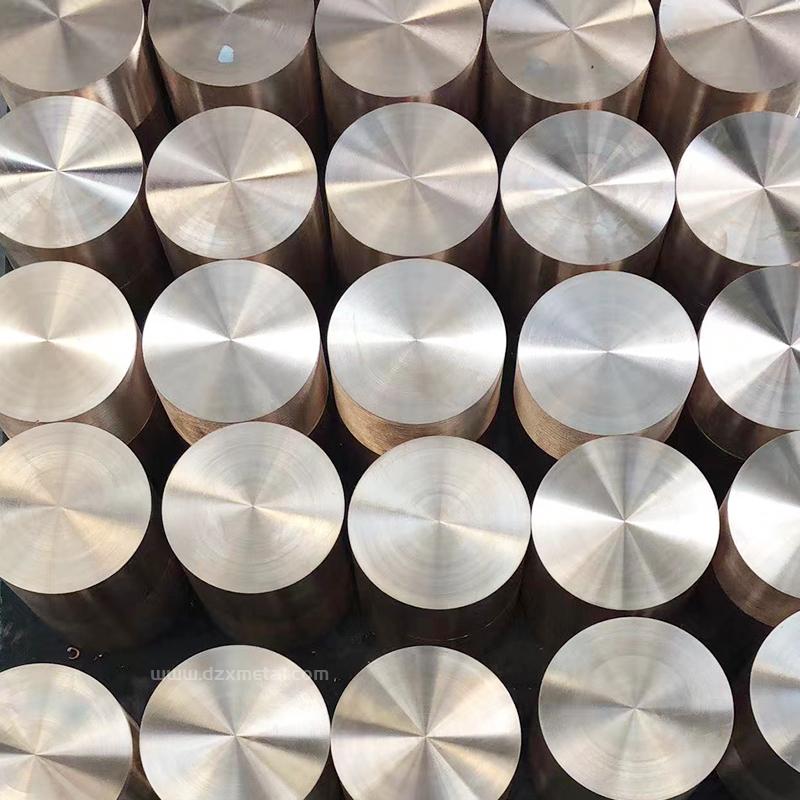

Wholesale Titanium Rod TA1 TC4 Grade 5 GR6 TI-6AL-4V 76MM High Purity Titanium Bar

- Product Details

Product Description

Titanium rods occupy an important position in modern industry due to their unique properties and wide range of applications. In the aerospace field, titanium rods are used to manufacture aircraft internal structural parts, engine parts, etc. due to their lightweight, high strength, high temperature resistance, and corrosion resistance. They effectively reduce the weight of the aircraft and improve fuel efficiency and flight performance. Titanium rods have a wide range of applications in ocean engineering, and are mainly used to manufacture deep-sea exploration equipment, ocean platform components, and seawater desalination equipment. Its excellent seawater corrosion resistance greatly extends the service life of the equipment. Due to the significant corrosiveness of the chemical environment, titanium rods are widely used in equipment in the chemical industry, such as heat exchangers, reactors and storage tanks. Titanium rods can effectively resist corrosion from strong acids and alkalis, ensuring long-term stable operation of the equipment.

Basic Info.

Standard of titanium rod

GB/T2965-2007、GB/T13810、Q/BS5331-91

ASTM B348、ASTM F136、ASTM F67、AMS4928

Grade of titanium rod

American label number: GR1, GR2, GR3, GR5, GR7, GR12, Ti6AL4V ELI, Ti6AL7Nb, Ti13Nb13Zr, Ti1533

Russian label number: BT1-00, BT1-0, BT1-2, etc.

Domestic brands: TAO, TA1, TA2, TA3, TA4, TA5, TA6, TA7, TA9, TA10, TB2, TC1, TC2, TC3, TC4, TC4ELI, TC11,

Surface of the titanium rod

Pickled surface Bright surface

Application of Titanium rod

Military, medical, sporting goods, glasses, earrings, headgear, electroplating hangers, welding wire and other industries.

State of titaniu Plate

| Brand | Method of making | State of supply | Specification(mm) | ||

| Thickness | Width | Length | |||

| TA1, TA2, TA3, TA4, TA5, TA6, TA7, TA9, TA10, TC1, TC2, TC3, TC4, TC4ELI, TC11, | Hot rolled | R,M | >4.75~60 | 400-3000 | 1000-4000 |

| Cold rolled | Y,M,ST | 0.3-6 | 400-1000 | 1000-3000 | |

| TB2 | Hot rolled | ST | >4-10 | 400-3000 | 1000-4000 |

| Cold rolled | ST | 1 - 4 | 400-1000 | 1000-3000 | |

| TBS,TB6,TBB | Cold rolled | ST | 0.3-4.75 | 400-1000 | 1000-3000 |

| China Stanard | Chemical Composition | American Standard | Russian standard | Japanese standard |

| TA1 | Industrial pure titanium | GR1 | BT1-0 | TP270 |

| TA1-1 | Industrial pure titanium (plate change) | GR1 | BT1-100 | |

| TA2 | Industrial pure titanium | GR2 | TP340 | |

| TA3 | Industrial pure titanium | GR3 | TP450 | |

| TA4 | Industrial pure titanium | GR4 | TP550 | |

| TA7 | Al Ti - 5-2.5 Sn | GR6 | BT5-1 | TAP5250 |

| TA8 | Ti - 0.05 - Pd | GR16 | ||

| TA8-1 | Ti-0.05Pd(plate change) | GR17 | ||

| TA9 | Ti - 0.2 - Pd | GR7 | TP340Pb | |

| TA9-1 | Ti - 0.2 - Pd | GR11 | ||

| TA10 | Mo Ti - 0.3-0.8 Ni | GR12 | ||

| TA11 | Ti-8AL-1Mo-1V | TI-811 | ||

| TA15 | Mo Ti - 6.5 - AL - 1-2-1 v zr | BT-20 | ||

| TA17 | Ti-4AL-2V | πT-3B | ||

| TA18 | Ti - 3-2.5 V | GR9 | OT4-B | TAP3250 |

| TB5 | Ti-15V-3AL-3Gr-3Sn | Ti-15333 | ||

| TC1 | Ti - 2 al - 1.5 Mn | OT4-1 | ||

| TC2 | Al Ti - 4-1.5 Mn | OT4 | ||

| TC3 | Ti-5AL-4V | BT6C | ||

| TC4 | Ti-6AL-4V | GR5 | BT6 | TAP6400 |

| TC10 | Ti 6 al - v - 2 Fe Cu sn - 0.5-0.5 | Tu-662 | ||

| TC24 | Ti - 4.5 - AL fe - 3 v - 2 mo - 2 | SP-700 |

High strength: The density of titanium alloy is generally about 4.51g/cubic centimeter, which is only 60% of steel. The density of pure titanium is close to that of ordinary steel. Some high-strength titanium alloys exceed the strength of many alloy structural steels.

High chemical activity: Titanium has high chemical activity, and has strong chemical reactions with O, N, H, CO, CO2, water vapor, ammonia, etc. in the atmosphere.

Good corrosion resistance: Titanium alloy works in humid atmosphere and seawater medium, and its corrosion resistance is better than stainless steel; it is particularly resistant to pitting corrosion, acid corrosion, and stress corrosion; it is resistant to alkali, chloride, gas, etc. Organic substances, sulfuric acid, etc. have excellent corrosion resistance.

Low temperature resistance: Titanium alloys can still maintain their mechanical properties at low and ultra-low temperatures. Titanium alloys with good low-temperature performance and extremely low interstitial elements, such as TA7, can maintain certain plasticity at -253°C.

High thermal strength: the use temperature of titanium is several hundred degrees higher than that of aluminum alloy, and it can still maintain the required strength at medium temperature, and can work for a long time at a temperature of 450~500°C. There is still a high specific strength in the high range, but the specific strength of aluminum alloy decreases obviously at 150C. The working temperature of titanium alloy can reach 500°C, while that of aluminum alloy is below 200°C.

Small thermal conductivity: the thermal conductivity of titanium = 15.24W/ (m.K) is about 1/4 of brocade, 1/5 of iron, and 1/14 of aluminum, and the thermal conductivity of various titanium alloys is about 1/4 that of titanium. 50% drop.

Excellent Weldability: Titanium wire can be easily welded and fabricated, allowing for diverse applications across different industries.

FAQ

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.