High Temperature 1200℃ Customized Hole Size Stainless Steel Band Heater 220V 600W With MICA

- Product Details

Describe of MICA Band Heater

MICA band heater is a type of electric heater used in industrial applications. It consists of a heating element encased in a mica insulation layer, which is then wrapped around a cylindrical object, such as a machine barrel or nozzle. MICA band heaters are valued for their efficient and uniform heating capabilities, as well as their durability and resistance to high temperatures. They are commonly used in processes like plastic extrusion and injection molding.

Applications of MICA Band Heater:

MICA band heaters are widely used in various industrial applications due to their efficient heating capabilities and durability. Here are some common applications:

Plastic Extrusion:

Barrel Heating: MICA band heaters are used to heat the barrel of extrusion machines to maintain a consistent temperature for melting and processing plastics.

Nozzle Heating: They also heat the nozzle to ensure smooth and precise extrusion of plastic materials.

Injection Molding:

Mold Heating: In injection molding machines, MICA band heaters are used to heat the mold cavities, which helps in maintaining the correct temperature for molding and improves the quality of the final product.

Packaging Machinery:

Sealing Bars: MICA band heaters are used to heat sealing bars in packaging machines, which helps in sealing plastic bags and other packaging materials efficiently.

Food Processing:

Equipment Heating: They are used in various food processing equipment to maintain consistent temperatures for melting or heating ingredients.

Chemical Processing:

Reactor Heating: In chemical reactors, MICA band heaters can be used to maintain the required temperature for chemical reactions.

Rubber Processing:

Calendering Machines: MICA band heaters are used in calendering machines to heat rollers for rubber processing.

Textile Industry:

Dyeing and Finishing: They are used in textile processing machines to maintain specific temperatures for dyeing and finishing fabrics.

Construction:

Heating Element: Made from materials like nickel-chromium (nichrome), this is the part that generates heat when electrical current passes through it.

Mica Insulation: Mica is a mineral with excellent thermal and electrical insulation properties. It surrounds the heating element to ensure that heat is directed efficiently toward the object and to prevent heat loss.

Metal Sheath: The mica insulation and heating element are enclosed in a metal sheath, which provides physical protection and allows for mounting on the cylindrical object.

Mounting: Band heaters are typically designed to be clamped or fastened around the object they are heating, such as a barrel or a nozzle.

Installing a MICA band heater involves several steps to ensure it operates effectively and safely. Here’s a step-by-step guide

Installation of MICA Band Heater:

1. Preparation:

Power Off:** Ensure the machine or equipment is turned off and disconnected from the power source.

Clean Surface: Clean the surface where the band heater will be installed to remove any debris or contaminants.

2. Check Compatibility:

Size and Fit:** Verify that the MICA band heater is the correct size and shape for the cylindrical object you are heating.

Voltage and Wattage:Confirm that the heater matches the voltage and wattage specifications required for your application.

3. Install the Heater:

-Position the Heater: Carefully position the MICA band heater around the cylindrical object. Align it so that it covers the area that needs heating.

-Secure the Heater: Use the provided clamps or fastening mechanisms to secure the heater in place. Ensure it is snug but not overly tight, which could damage the heater or the object.

-Check Alignment: Make sure the heater is evenly aligned and covers the intended heating area without gaps or overlaps.

4. Electrical Connections:

- Connect Wires: Connect the heater’s electrical leads to the power supply. Ensure that connections are secure and follow any wiring diagrams or instructions provided with the heater.

- Insulate: If necessary, insulate the connections to prevent electrical hazards.

5. Testing:

- Power On: Reconnect the power supply and turn on the equipment.

- Monitor: Check the heater’s operation to ensure it is heating correctly. Monitor for any irregularities such as uneven heating or unusual noises.

6. Safety Checks:

- Inspect for Leaks: Ensure there are no electrical or heat leaks.

- Verify Temperature: Use a thermometer or temperature probe to verify that the heater reaches and maintains the desired temperature.

7. Maintenance:

- Regular Inspection: Periodically inspect the MICA band heater for signs of wear or damage.

- Cleaning: Keep the heater and the surface clean to ensure optimal performance.

Notes:

- Avoid Overheating: Do not exceed the heater’s maximum temperature rating to avoid damage.

- Consult Manufacturer: Always refer to the manufacturer’s installation instructions and guidelines specific to your MICA band heater model.

Proper installation is crucial for the effective operation and longevity of a MICA band heater. Following these steps helps ensure that the heater performs efficiently and safely.

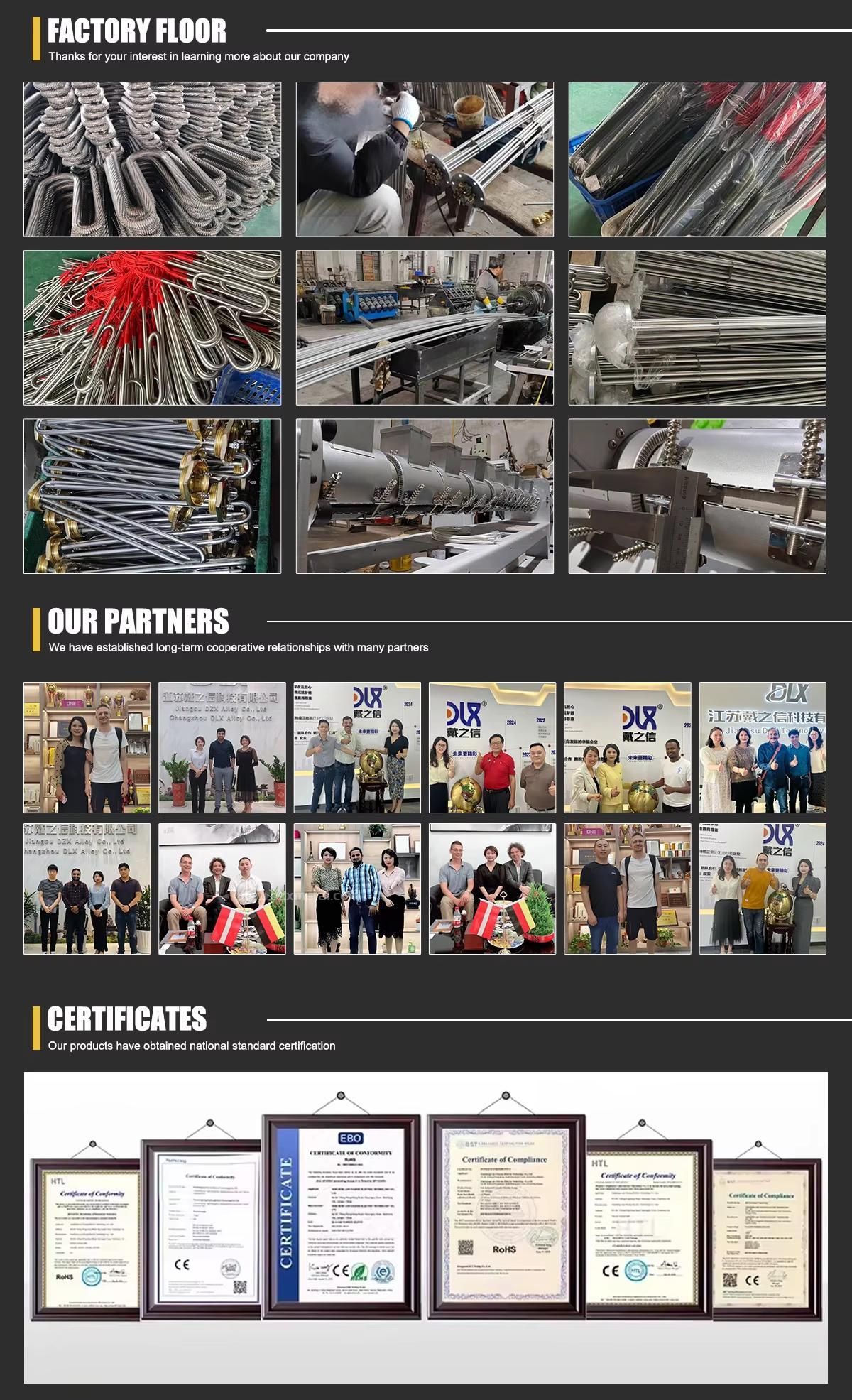

About DZX Technology:

Jiangsu DZX Technology Co,Ltd. is a professional engaged in the electric heater design, manufacture and sales of integrated entity enterprise, has over 20 years experience in electric heater of scientific research and production.

Our main product is heating resistance wire. heater elements and thermocouple series products

Enterprise has core technology advantage and introduce advanced technology and management concept, in accordance with the 1s09001 quality management requirements, strict control of raw materials quality,perfect detection means, with first-class technology,reliable quality and excellent service to win customers praise and praise.