Mica Band Heater Ring With 304 316 Stainless Steel Sheath For Heating Extruder Machine

- Product Details

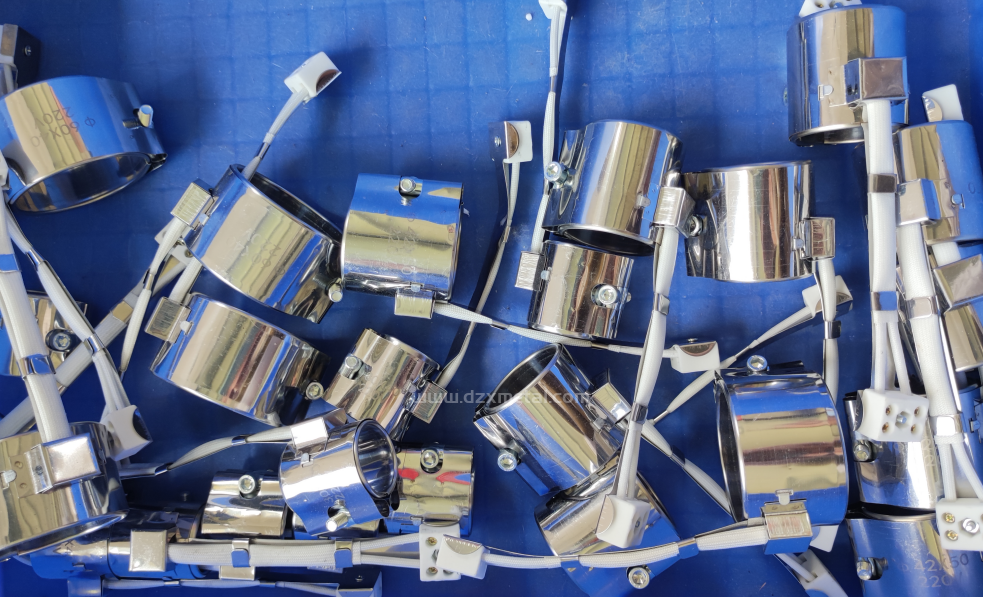

MICA Band Heater

mica heater is a type of electrical heating device that uses mica as a heating element. Mica is a mineral that has excellent thermal and electrical insulating properties, making it an ideal material for use in heaters.

Design and Functionality

Heating Element:

Material: Mica heaters typically use a metal heating element, such as nichrome (nickel-chromium alloy), which is embedded between layers of mica. Nichrome is chosen for its resistance to oxidation and high-temperature stability.

Construction: The metal element is usually coiled or in a flat strip form and is directly in contact with the mica sheets. This design allows for efficient heat transfer.

Mica Sheets:

Properties: Mica is a naturally occurring mineral that is highly heat-resistant and electrically insulating. It can withstand high temperatures without degrading, which is crucial for the longevity and efficiency of the heater.

Function: Mica sheets act as a heat conductor and an insulator. They help to direct the heat generated by the metal element to the desired area and protect surrounding components from heat damage.

Heat Distribution:

Uniform Heating: Mica's thermal properties help to distribute heat evenly across the surface of the heater, minimizing hot spots and ensuring consistent warmth.

Convection: In some designs, mica heaters may incorporate a fan to enhance air circulation and improve heat distribution throughout the room.

Advantages of MICA Band Heater

Efficient Heating:

Mica heaters provide rapid and efficient heating due to the excellent thermal conductivity of the mica sheets, which allows the heater to reach its operating temperature quickly.

Durability:

Mica's resistance to high temperatures and its non-reactive nature contribute to the heater's long lifespan. Mica heaters are generally robust and can withstand prolonged use.

Safety:

The insulating properties of mica help to prevent the exterior of the heater from becoming excessively hot, reducing the risk of burns or fire hazards.

Low Maintenance:

Mica heaters typically require minimal maintenance compared to other heating technologies. The mica sheets are resistant to dust and dirt buildup, which can reduce the frequency of cleaning.

MICA Band Heater Details

Applications of MICA Band Heater

Plastic Injection Molding

Purpose: To heat the barrel of an injection molding machine to maintain the temperature of the plastic as it is melted and injected into molds.

Benefits: Provides consistent and efficient heating, which is crucial for precise molding and preventing defects in plastic parts.

Extrusion Processes

Purpose: To heat extruder barrels used in the extrusion of plastic, rubber, or other materials.

Benefits: Ensures uniform temperature control along the length of the extruder, which helps in producing consistent product quality.

Packaging Equipment

Purpose: Used in machines that seal or wrap products, such as in the heat sealing of packaging materials.

Benefits: Helps in achieving reliable sealing and packaging by providing precise and even heat.

Food Processing

Purpose: To maintain temperatures in equipment used for cooking, melting, or heating food products.

Benefits: Stainless steel's resistance to corrosion and contamination makes it suitable for food-grade applications, ensuring hygiene and durability.

Chemical Processing

Purpose: To provide controlled heating in reactors, tanks, and other chemical processing equipment.

Benefits: Stainless steel’s resistance to chemicals and high temperatures makes it ideal for harsh environments.

Textile Industry

Purpose: Used in machines that require controlled heating, such as in the dyeing or finishing of fabrics.

Benefits: Provides stable and uniform heat to ensure consistent quality in textile processing.

Automotive Manufacturing

Purpose: Applied in various automotive manufacturing processes, including heating components and tools used in production.

Benefits: The heater’s durability and high-temperature performance are well-suited for the demanding conditions in automotive manufacturing.

Metal Processing

Purpose: For heating metals in various processing applications such as forging or annealing.

Benefits: Ensures precise temperature control, which is critical for achieving desired metal properties.

Company Information:

Jiangsu DZX Technology Co,Ltd. is a professional engaged in the electric heater design, manufacture and sales of integrated entity enterprise, has over 20 years experience in electric heater of scientific research and production.

Our main product is heating resistance wire. heater elements(Cartridge Heater; Ceramic Band Heater ; MICA Band Heater; Tubular Heater ; Immersion Heater ; Flange Heater; Water Heater etc) and thermocouple series products

Enterprise has core technology advantage and introduce advanced technology and management concept, in accordance with the 1s09001 quality management requirements, strict control of raw materials quality,perfect detection means, with first-class technology,reliable quality and excellent service to win customers praise and praise.

Shipping details: