220V 380V 440V Heating Customized Power 230V 500w 380V 220V 2300W Cartridge Heaters

- Product Details

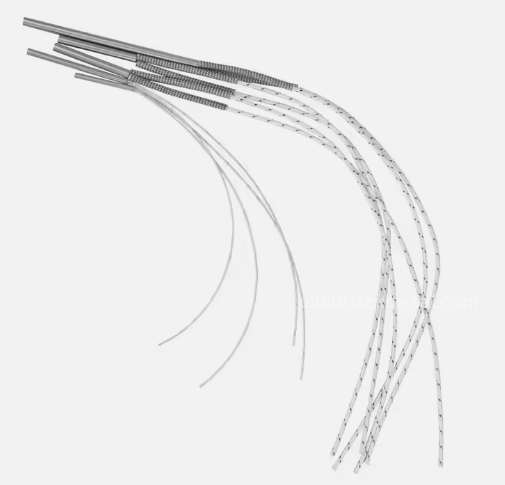

Cartridge Heater s

Cartridge heaters are compact, cylindrical heating elements widely used in industrial applications where precise and localized heat is required. Here’s a detailed overview of cartridge heaters:

Key Features of Cartridge heaters:

Construction: Cartridge heaters are typically made with a metal sheath (often stainless steel) that houses a heating element. The element is usually a coil of resistance wire or a flat wire that is insulated and positioned inside the sheath. The metal sheath helps transfer heat to the object being heated.

Design: They come in various diameters and lengths, allowing for customization based on the specific heating needs. They are designed to fit snugly into holes or cavities within machinery or equipment.

Applications:

Injection Molding: Used to heat molds and maintain consistent temperatures for plastic or metal parts.

Extrusion: Applied to heat barrels and nozzles in extrusion processes.

Packaging: Used in heat sealing applications.

Laboratory Equipment: Provides precise heating for various lab instruments.

Advantages:

Efficient Heat Transfer: Due to their compact size and direct contact with the heated object, cartridge heaters can provide efficient and targeted heating.

Fast Heating: They offer rapid heat-up times and can reach high temperatures quickly.

Durability: The metal sheath is designed to withstand harsh conditions, including high temperatures and corrosive environments.

Temperature Control: Cartridge heaters can be integrated with temperature controllers and sensors to maintain precise temperature settings, which is crucial for applications requiring consistent heat.

Installation: They are generally installed by inserting them into pre-drilled holes or cavities in equipment or machinery. Proper fit is important to ensure good thermal contact and effective heat transfer.

Considerations When Choosing Cartridge Heaters:

Size and Shape: Ensure the heater fits the application’s space and heating requirements. Different diameters and lengths are available to match various needs.

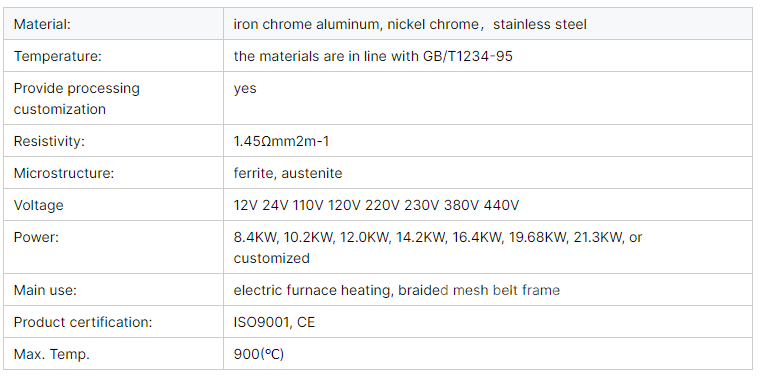

Wattage and Voltage: Choose based on the power requirements of your application. Wattage determines the amount of heat the heater can produce, while voltage must match your power supply.

Temperature Range: Ensure the heater can operate within the required temperature range for your application.

Material: The sheath material should be compatible with the environment in which the heater will be used. Stainless steel is commonly used due to its resistance to corrosion and high temperatures.

Custom Features: Some applications may require custom features like special lead wires, different mounting options, or specific resistance wire configurations.

Products Description

Features

1 Made of high quality magnesium oxide, solid stainless steel flange laser welding

2. Sufficient materials are used, not easy to deform after long-term use, and the stainless steel tube has a long service life

This heaters are widely used in making industrial heating equipments and domestic heating appliances.Heat treatment furnaces,far infrared heating devices,starting and braking resistors for electrically driven locomotive,liquified gas infrared heat resistant nets and tail gas purifiers for auto car are the main applications in the industrial field.Do-mestic applications are such as cooking,ironing,drying,heating of fluids,heating of beds,space heating and etc.

A number of heating pipes are welded or screwed to a flange to form a high-power electric heat pipe that can be disassembled as a whole. It is often used in large water tanks, boilers, heat conduction oil furnaces and other heating places In the raw material, choose SUS304 or SUS316 thickened stainless steel, high temperature resistance wire and high temperature insulation.

Designed to reduce the heating tube surface load, can be heated in water and oil

Internal wiring series:

This series of heating rods eliminates the safety disadvantages of external wires and

the problems of repeated bending and wear.

The internal wiring cable can withstand a temperature of 500°C, the surface

temperature of the heating rod is less than 700°C, The mold can be heated up to500°C

External wiring series:

the surface temperature of the heating rod is <879°C, and the mold can be heated to 700°C Made of imported materials, it has a

longer service life than the economical series Recommended heat flux <25W/m (refer to the engineer's design drawing for the specific load)

Flange head series:

This series is customized waterproof models for different environments, suitable for waterproof environments

Scientific structural design improves product safety and life The use of high-quality source materials is more stable in quality

Product packaging

Over the years, we have worked hard to promote and realize the modernization of alloy sales, and actively cultivated and enhanced the ability of employees' independent innovation. All-round renovation and upgrade of the original business site, facilities and equipment, and modern computer management. Hope to establish long-term partnerships and win market reputation.

We are increasing thescale of trade and customers through out the world. With our good reputation we have won the trust of our customers. It's helps the modernisation of our country and promote the economic and technical exchanges with the rest of the world. We also look forward to enhance the friendship with other countries and make positive impact.

We warmly hope that you and us together, hand in hand, create a glorious future.

FAQ

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.

High Watt 12V 1000W Cartridge Heater With K Type Thermocouple And Screw Connection

High Temperature 220V 110V 380V Cartridge Heater With Inner Wire For Cladding Machine

Electric Cartridge Heater 220V 380V with Incoloy Pipe for Bottle Capping Machine

Customized Size 500W 220V Voltage Cartridge Heater With Stainless Steel Tube For Plastic Rubber Mold