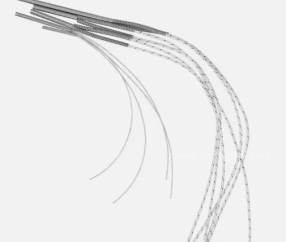

Electric Cartridge Heater 220V 380V with Incoloy Pipe for Bottle Capping Machine

- Product Details

Cartridge Heater Description

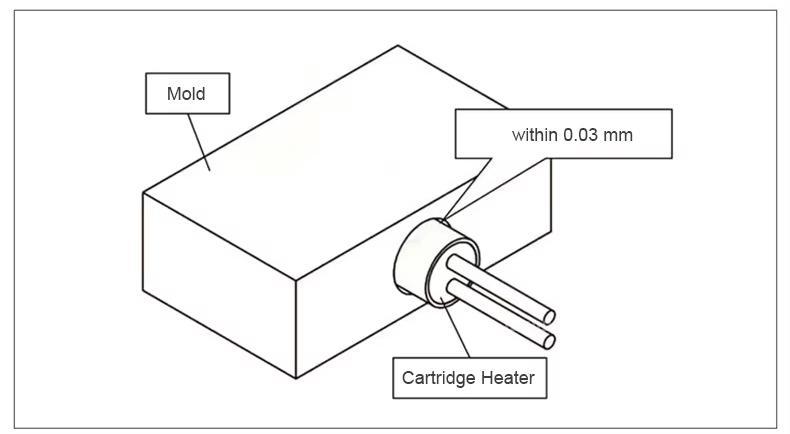

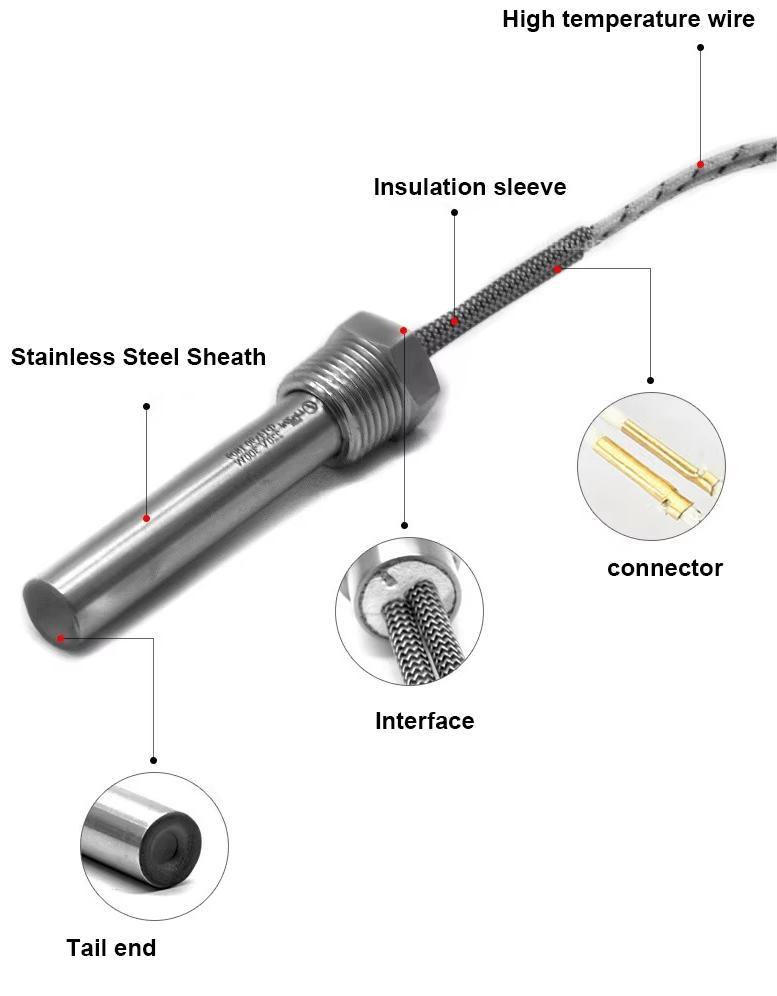

A cartridge heater, also known as a card-type electric heating tube or cartridge electric heating tube, is a small-volume, high-efficiency, high-watt-density heating element. It can be inserted into small metal holes or gaps, offering superior performance and strong heating capacity. High-temperature single-head heaters require precise manufacturing.

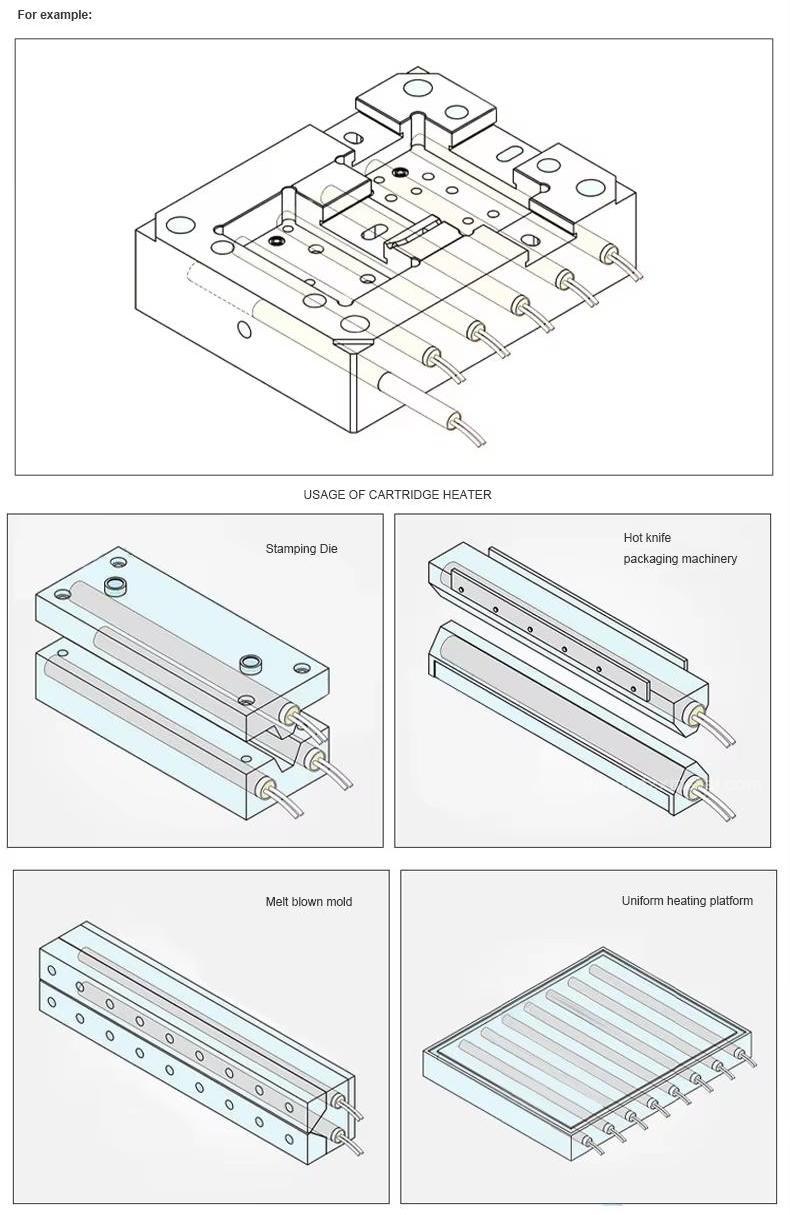

1. Applications

Cartridge heaters are suitable for heating media where wiring cannot be done at both ends, such as high and low-temperature insertion heating for various large and small molds and mechanical equipment. This includes punching dies and other molds, medical equipment, plastic sealing machines, bottle capping machines, continuous automatic sealing machines, and cigarette-making machines.

2. Main Pipe Materials

1. Stainless steel SUS316 or 304, with a usage temperature of up to 550°C.

2. High nickel alloy tube Incoloy 800 or 840, with a usage temperature of up to 750°C.

3. Performance Requirements

- Heat-Up Time

Under the test voltage, the time for the component to rise from ambient temperature to the test temperature should not exceed 15 minutes.

- Rated Power Deviation

Under sufficient heating conditions, the deviation of the rated power of the component should not exceed the following specified range:

- For components with rated power less than or equal to 100W: ±10%.

- For components with rated power greater than 100W: +5% to -10% or 10W, whichever is greater.

- Leakage Current

The cold leakage current and the leakage current after water pressure and sealing tests should not exceed 0.5mA.

The hot leakage current at working temperature should not exceed the calculated value in the formula, but the maximum should not exceed 5mA.

When multiple components are connected in series to the power supply, the leakage current test should be carried out on this group of components as a whole.

- Insulation Resistance

The cold insulation resistance should be no less than 50MΩ during factory inspection.

After the sealing test, the insulation resistance after long-term storage or use should not be less than 1MΩ.

The hot insulation resistance at working temperature should not be lower than the calculated value in the formula, but the minimum should be no less than 1MΩ.

Formula:

R ={10 - 0.015T/t}*0.001

R — Hot insulation resistance (MΩ)

t — Heating length (mm)

T — Working temperature (℃)

- Insulation Withstand Voltage

The component should be maintained under the specified test conditions and test voltage for 1 minute without flashover and breakdown.

- Ability to Withstand Power On and Off

The component should be able to undergo 2000 power on and off tests under the specified test conditions without damage.

- Overload Capacity

The component should withstand 30 cycles of overload tests under the specified test conditions and input power without damage.

- Heat Resistance

The component should withstand 1000 cycles of heat resistance tests under the specified test conditions and test voltage without damage.

Packing Details:

When using cartridge heaters, it's important to follow safety precautions to ensure safe operation and prevent damage to the heater or equipment. Here are some key precautions:

1. Proper Installation

- Ensure the heater is installed correctly in a suitable mounting hole.

- Use appropriate thermal paste or grease to improve heat transfer and prevent air pockets.

2. Avoid Overheating

- Do not exceed the maximum temperature rating of the cartridge heater.

- Implement temperature controls or sensors to monitor the cartridge heater’s temperature.

3. Electrical Safety

- Ensure proper electrical connections and insulation to prevent short circuits.

- Use a circuit breaker or fuse to protect against overcurrent.

. Regular Maintenance

- Inspect cartridge heaters regularly for signs of wear, damage, or corrosion.

- Clean any dust or debris that may accumulate on or around the cartridge heater.

5. Avoid Moisture

- Keep heaters dry and free from moisture to prevent electrical hazards.

- Avoid using them in environments with high humidity unless they are specifically rated for such conditions.

6. Use Appropriate Power Supply

- Ensure the power supply matches the specifications of the cartridge heater.

- Use a power supply that can handle the required voltage and current.

7. Thermal Expansion

- Allow for thermal expansion when installing heaters in confined spaces.

- Ensure there is sufficient clearance around the heater for heat dissipation.

8. Handling and Storage

- Handle with care to avoid physical damage.

- Store in a dry, cool place when not in use.

9. Follow Manufacturer Guidelines

- Always adhere to the manufacturer’s instructions and guidelines for installation, operation, and maintenance.

About Us:

Jiangsu DZX Technology Co,Ltd. is a professional engaged in the electric heater design, manufacture and sales of integrated entity enterprise, has over 20 years experience in electric heater of scientific research and production.

Our main product is heating resistance wire. heater elements and thermocouple series products

Enterprise has core technology advantage and introduce advanced technology and management concept, in accordance with the 1s09001 quality management requirements, strict control of raw materials quality,perfect detection means, with first-class technology,reliable quality and excellent service to win customers praise and praise.

220V 380V 440V Heating Customized Power 230V 500w 380V 220V 2300W Cartridge Heaters

High Watt 12V 1000W Cartridge Heater With K Type Thermocouple And Screw Connection

High Temperature 220V 110V 380V Cartridge Heater With Inner Wire For Cladding Machine

Customized Size 500W 220V Voltage Cartridge Heater With Stainless Steel Tube For Plastic Rubber Mold