China Hot Sale 110V220V Water Heater Flexible Tube Spiral Heater

- Product Details

Key attributes

Industry-specific attributes

Other attributes

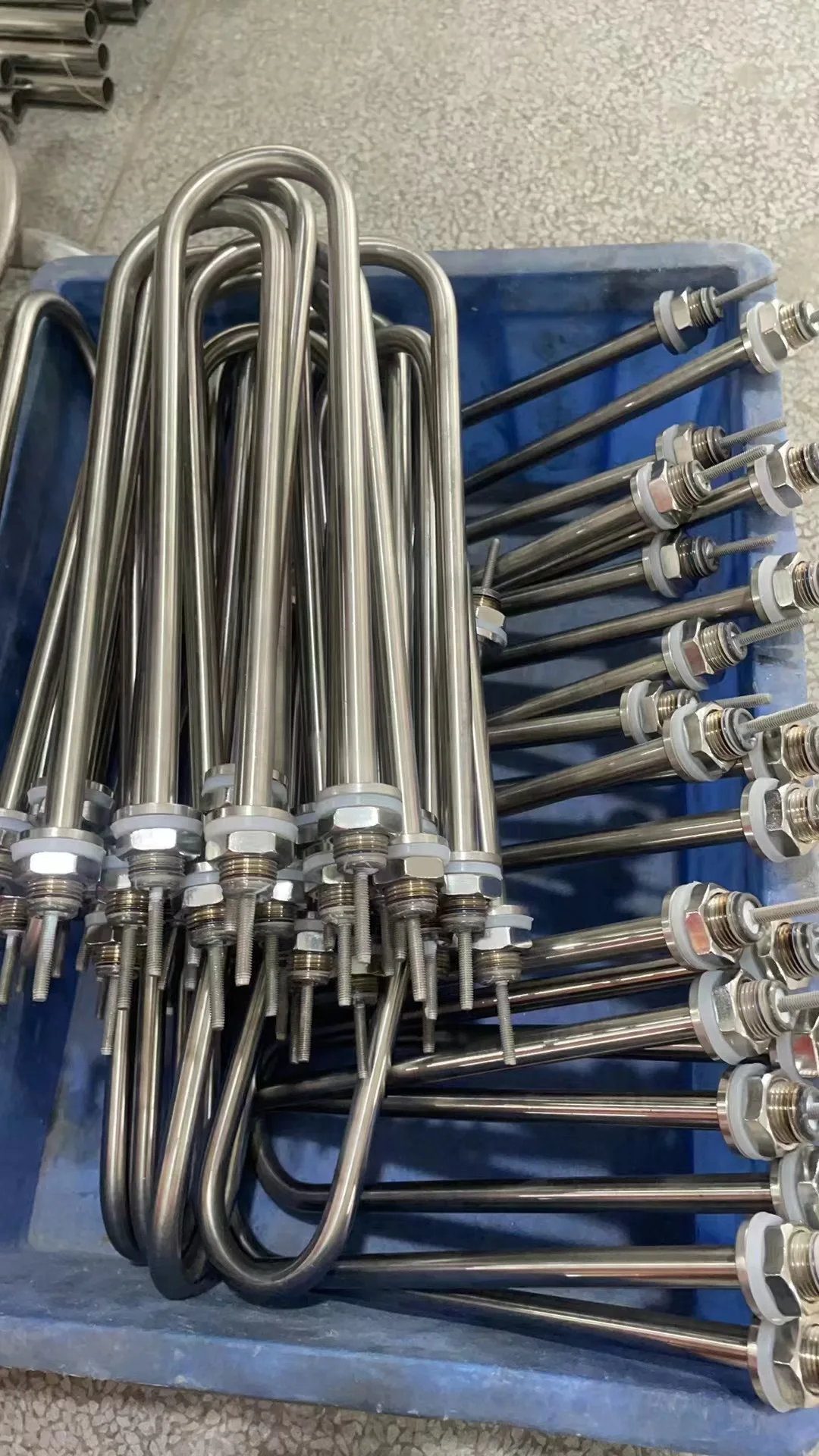

Multiple heating tubes are connected to the flange by welding or threading to form a high power electric heater that can be disassembled as a whole. This kind of device is commonly used in large water tanks, boilers, thermal oil furnaces and other heating places. The raw materials used are SUS304 or SUS316 thickened stainless steel, high-temperature resistant resistance wire and high-temperature resistant insulating materials.

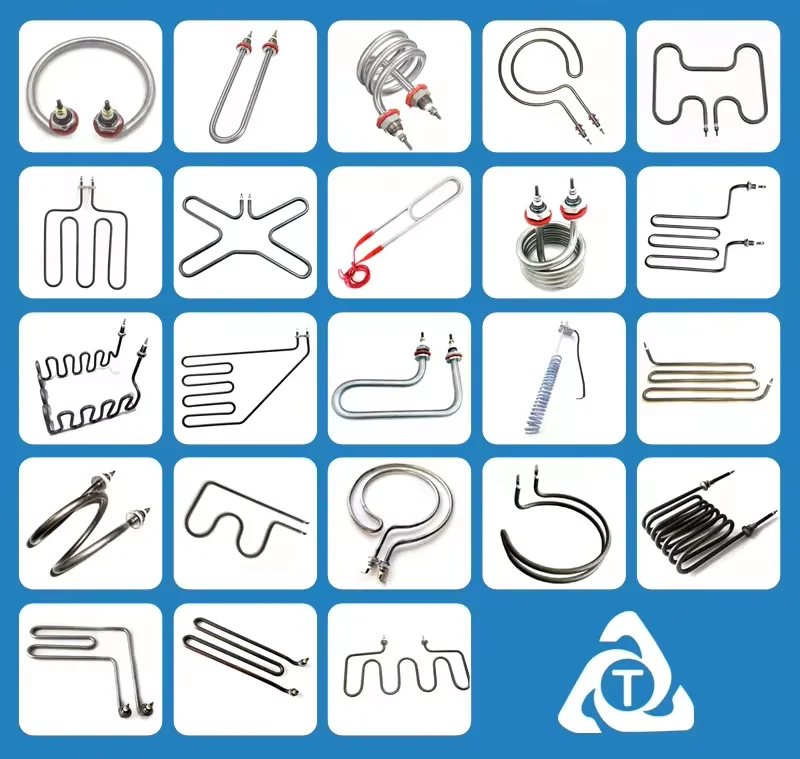

The heating element can be designed into various shapes according to customers' requirements, and it is directly immersed in liquids, such as water, oil, solvents, process solutions, molten materials, as well as air and gas. Tubular heaters are manufactured in Incoloy alloy, stainless steel or copper sheathing materials and are available with a variety of end connection styles.

Magnesium insulation provides improved thermal conductivity. Tubular heaters can be used in virtually any application. Straight tubes can be embedded in the process bath for thermal conduction, while moulded tubular heaters can provide constant and stable heat in any particular application. Applications include: plastics processing machinery, the engineering industry, packaging machinery, shoe machinery, foundry equipment, radiant surface heating, hot runner mould systems and more.

The product advantages of Tubular Heater are as follows:

Highly efficient heat transfer: Tubular heaters are insulated with magnesium, which has excellent heat transfer performance and can quickly and evenly transfer heat to the medium being heated.

Strong durability: the use of Incoloy alloy, stainless steel or copper and other high-quality sheath materials, with good corrosion resistance and oxidation resistance, to ensure that the heater in harsh environments, long life use.

Flexible design: the heating element can be customised into a variety of shapes and sizes according to customer requirements, suitable for a variety of heating occasions, including the heating of liquids, air and gas.

Multiple application scenarios: Tubular heaters can be used in a wide range of industrial applications, such as plastics processing machinery, packaging machinery, engineering equipment, casting equipment and hot runner mould systems, etc., and are widely applicable.

Easy to install: Tubular heaters are designed for easy integration into existing equipment and are available in a variety of end connection styles for easy installation and maintenance.

High Reliability: Through precise manufacturing processes and quality material selection, tubular heaters are able to maintain consistent performance over extended periods of operation, reducing downtime and maintenance costs.

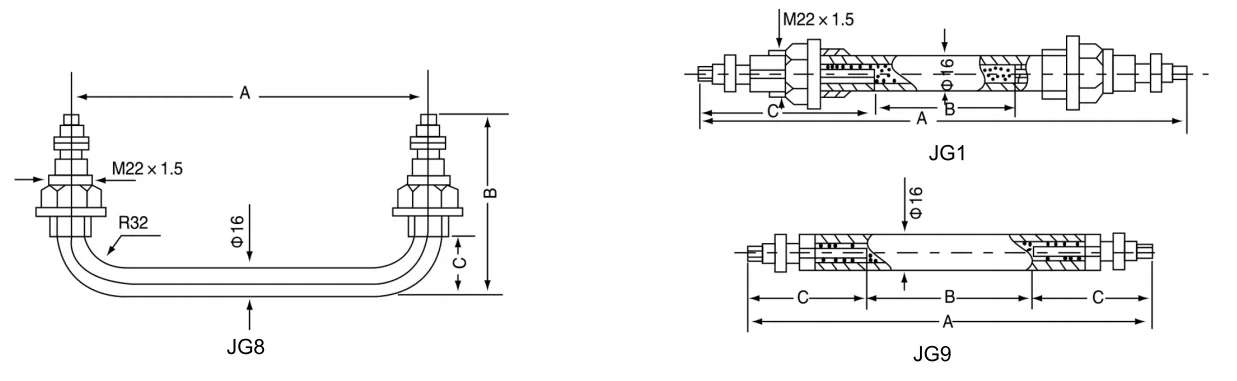

Product Name | 230v 350w 400w 500w 800w 1000w U W I shape Industrial electric rod immersion water heating element tubular tube heater |

Heating wire | Precision helical wound nickel-chrome resistance wire |

Certification | ISO9001, CE |

Insulation Material | High purity magnesium oxide powder compacted |

Voltage | 120V, 240V, 480V, 600V and so on |

Power | 50-2000W, or customized |

Tube Diameter | 6MM 8MM 10MM 12MM 14MM 16MM 18MM 20MM |

Thread size | M12 M14 M16 M18 M20 M22 |

Tube Material | Copper ,Steel,Incoloy,Titanium |

How to Choose The right Material for the tubular heaters? Please check this table. | |

Material | Maximum Sheath Temperature |

Copper | 350℉(170℃) Application: Water, Oil, Grease |

Steel | 750℉(400℃) Application: Alkaline cleaning solutions, Tars, Asphalt or air heating |

Stainless Steel | 1200℉(600℃) Application: Corrosive liquids, food processing equipment, Radiant heating |

Incoloy | 1500℉(815℃) Application: Cleaning and degreasing solutions, Corrosive liquids |

Tube Diameter | 6MM 8MM 10MM 12MM 14MM 16MM 18MM 20MM |

Thread size | M12 M14 M16 M18 M20 M22 |

Tube Material | Copper ,Steel,Incoloy,Titanium |

Over the years, we have worked hard to promote and realize the modernization of alloy sales, and actively cultivated and enhanced the ability of employees' independent innovation. All-round renovation and upgrade of the original business site, facilities and equipment, and modern computer management. Hope to establish long-term partnerships and win market reputation.

We are increasing thescale of trade and customers through out the world. With our good reputation we have won the trust of our customers. It's helps the modernisation of our country and promote the economic and technical exchanges with the rest of the world. We also look forward to enhance the friendship with other countries and make positive impact.

We warmly hope that you and us together, hand in hand, create a glorious future.

DZX TECH, which is a factory for heating elements more than 22 years, we are founded in 2002, and run business with resistance alloy first. And in past 20 years, we R&D new product such as Heater Emelent , air heating and water heater elements and other alloy products.

FAQ

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.