L U Type Straight Electric Tubular Heater 230V 1500W with Stainless Steel Flexible Tube

- Product Details

Tubular Heater

A tubular heater is a widely used heating element that consists of a metal tube encasing a heating element. It's known for its versatility, efficiency, and durability in various heating applications.

Construction and Components:

Metal Tube:

Material: Typically made from high-grade metals like stainless steel or other corrosion-resistant materials to ensure longevity and withstand high temperatures.

Purpose: Acts as a protective sheath for the heating element inside, providing structural integrity and resistance to environmental factors.

Heating Element:

Material: Usually constructed from high-resistance alloys such as nickel-chromium (nichrome) or iron-chromium-aluminum (FeCrAl).

Function: Converts electrical energy into heat through electrical resistance.

Insulation:

Material: Often includes magnesium oxide or other insulating materials packed inside the tube to improve heat transfer and prevent energy loss.

Purpose: Enhances the efficiency of heat transfer to the surrounding environment and provides electrical insulation.

Design Flexibility:

Shapes and Configurations:

Straight: Common for simple, direct applications.

Bent or Coiled: Customized for specific applications requiring complex heating patterns or fitting into confined spaces.

Sizes and Wattages:

Customization: Available in various diameters, lengths, and wattages to match specific heating requirements.

Performance Characteristics:

Temperature Range:

Capability: Can operate at temperatures ranging from moderate to high, typically up to 600°C (1112°F), depending on the design and materials used.

Efficiency:

Heat Distribution: Provides even and consistent heating across the length of the tube, improving process stability and energy efficiency.

Durability:

Robustness: Designed to be durable and withstand harsh conditions, including high temperatures and corrosive environments.

Applications of Tubular Heaters

Process Air & Gas Heating:

Purpose: Used to heat air or gases in industrial processes, improving efficiency and controlling temperature for various operations.

Examples: Air dryers, industrial ovens, and gas heaters.

Water / Liquid Immersion:

Purpose: Provides direct heating of water or other liquids by immersing the heater in the liquid.

Examples: Water heaters, industrial tanks, and chemical processing.

Circulation Heating:

Purpose: Maintains the temperature of fluids in circulation systems, ensuring consistent heating throughout the system.

Examples: Heating circuits in heat exchangers, and circulation tanks.

Tank Wall and Pipe Heating:

Purpose: Applies heat to the walls of tanks and pipes to prevent freezing, maintain temperature, or ensure proper flow.

Examples: Insulated tanks, piping systems in cold environments.

Thermal Forming Machines:

Purpose: Provides the necessary heat to mold or shape materials in thermal forming processes.

Examples: Thermoforming machines for plastics and metal molds.

Furnace and Oven Heating:

Purpose: Used to heat the interior of furnaces and ovens for various industrial and commercial applications.

Examples: Industrial furnaces, commercial baking ovens.

Comfort Heating and Freeze Protection:

Purpose: Provides warmth in residential or commercial spaces and protects pipes or equipment from freezing temperatures.

Examples: Space heaters, pipe freeze protection systems.

Radiant Heating:

Purpose: Delivers heat directly to objects or surfaces via radiation, rather than heating the air.

Examples: Radiant heaters in workshops, garage heaters.

Vacuum Heating:

Purpose: Operates in a vacuum environment to heat materials or equipment without the need for a traditional heating medium.

Examples: Vacuum ovens, vacuum drying applications.

Metal Mold and Die Heating:

Purpose: Provides controlled heating to metal molds and dies in manufacturing processes to improve molding and forming.

Examples: Die casting, injection molding.

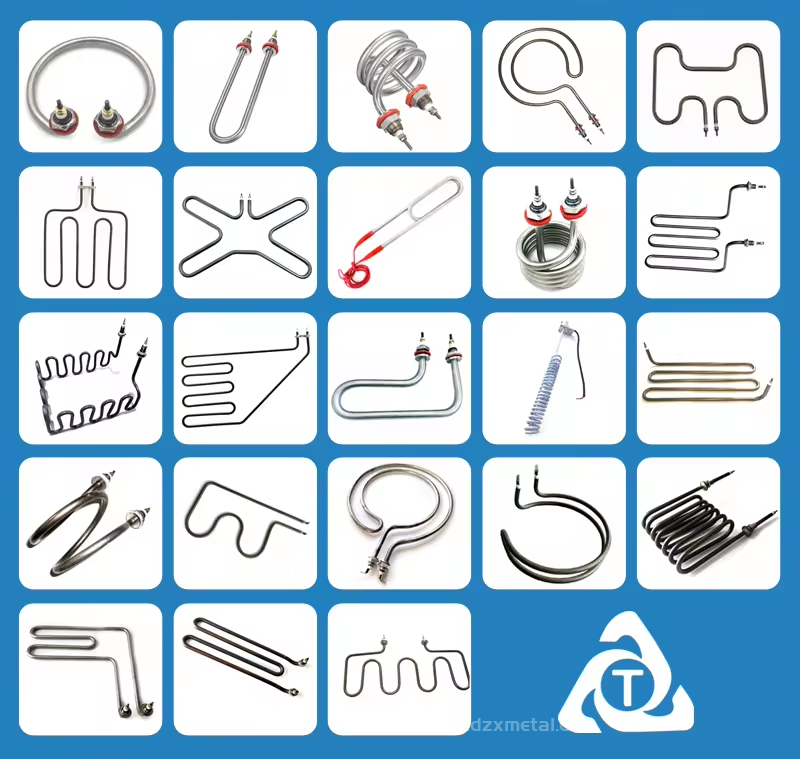

Shapes of Tubular Heaters

Straight Tubular Heaters:

Description: Simple, linear shape with a uniform diameter along its length.

Applications: Ideal for direct heating applications and easy installation in tanks, ovens, and dryers.

Bent Tubular Heaters:

Description: Tubes bent into specific shapes or angles to fit around equipment or into tight spaces.

Applications: Used in custom applications where the heater needs to conform to a specific layout, such as heating elements in confined areas or complex molds.

Coiled Tubular Heaters:

Description: Tubular heaters coiled into spiral or helical shapes.

Applications: Effective for heating larger surface areas or for use in applications like conveyor belts and fluid heating.

U-Shaped Tubular Heaters:

Description: Formed into a U-shape, often used to provide heating in applications where a directional heat source is needed.

Applications: Commonly used in industrial ovens and heating systems where the heater needs to be positioned around an object or within a chamber.

Custom-Shaped Tubular Heaters:

Description: Designed to meet specific dimensions and configurations based on the application’s needs.

Applications: Tailored for unique equipment or processes, such as custom molds, specialty tanks, or other bespoke heating requirements.

About DZX TECH