OEM Factory Barrel Ceramic Band Heater Infrared Ceramic Drums Plastic Extruder Band Heater For Heat

- Product Details

A ceramic band heater is a type of electric heater used to provide consistent heat to cylindrical objects, often in industrial and manufacturing settings. These heaters are particularly effective for applications where precise temperature control is required. Here’s a quick rundown of their key features and uses:

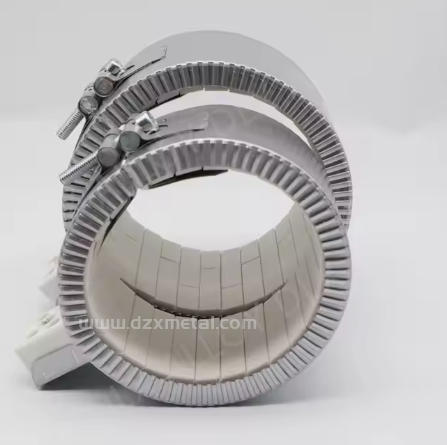

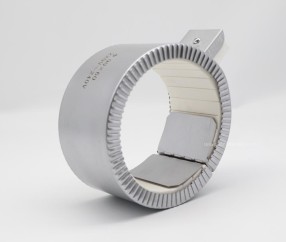

Construction: Ceramic band heaters typically consist of a ceramic core that is encased in a metal sheath. The ceramic material provides excellent thermal insulation and allows for even heat distribution.

Heating Element: Inside the ceramic core, there are often coiled or spiral heating elements made of materials like nickel-chromium or kanthal. These elements are responsible for generating heat when electricity passes through them.

Applications: They are commonly used to heat cylindrical parts in extrusion processes, injection molding machines, and in various industrial applications where precise temperature control is crucial. They can be used on equipment such as barrels, nozzles, or pipes.

Advantages: Ceramic band heaters are known for their efficiency and durability. They can provide uniform heat, which helps in reducing hot spots and improving the quality of the finished product. They also have a relatively quick heat-up time and can reach high temperatures.

Installation: They are designed to wrap around the object being heated and are usually secured in place with metal bands or clamps. Some models come with adjustable fittings to accommodate different sizes and shapes.

Temperature Control: These heaters can be equipped with temperature sensors and controllers to maintain precise heat levels, which is essential for processes that require strict temperature control.

Product name | Ceramic heating ring |

Normal temperature | 300-500℃ |

Voltage specification | 36V/110V/220V/380V/400V/440V |

Product features | Rapid heating, high thermal efficiency |

Product power | Customized on demand |

Product specifications | Various specifications non-standard customization |

Product use | Widely used in injection molding machine, extruder, film blowing machine, cutting machine and so on |

Usage | 1, the working voltage shall not exceed 10% of the rated value 2, the wiring part should be placed outside the heating layer and insulation layer, the shell should be effectively grounded 3,should be stored in a dry place |

Description

Product name: ceramic heating ring/Band Heater ElementsProduct features: uniform heating, high thermal efficiencyWhether to customize: Yes (customized power, voltage, outer diameter,inner diameter, height, wiring, etc.)

Scope of application: chemical industry, machinery, petroleum,shipbuilding, textile, metallurgy and other industries

1, heating ring size: inner diameter (mm)* height (mm)

2, voltage: such as: 380V, 240V, 230V, 220V, 110V,36V, 24V, 9V, etc.

3, power: We generally do in accordance with a square centimeter 3-5 watts, if there are special needs, please contact the seller

4, can open holes: square hole round hole

5, appearance: ceramic joints, high temperature line, screw outlet plug outlet line flexible and changeable

6, stainless steel heating plate is widely used in industrial equipment mold heating, chemical reagent heating and so on. Safe, stable and long life

Fix and tighten the heating ring, the temperature does not leak out to save electricity, the cover is not hot to touch by hand, and the work is safe

High quality joint

Simple wiring, safe use, easy installation, good insulation

Selected ceramic strip

Rapid heating, fast heat transfer efficiency, is twice the heating temperature of stainless steel heating ring

Stainless steel case

Aluminum plate shell, aluminum plate material is not easy to change color at 300-500 degrees high temperature appearance

Over the years, we have worked hard to promote and realize the modernization of alloy sales, and actively cultivated and enhanced the ability of employees' independent innovation. All-round renovation and upgrade of the original business site, facilities and equipment, and modern computer management. Hope to establish long-term partnerships and win market reputation.

We are increasing thescale of trade and customers through out the world. With our good reputation we have won the trust of our customers. It's helps the modernisation of our country and promote the economic and technical exchanges with the rest of the world. We also look forward to enhance the friendship with other countries and make positive impact.

We warmly hope that you and us together, hand in hand, create a glorious future.

FAQ

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.

5000W Oil Heater Band Induction Ring Heating Element Ceramic Extruder Band Heater For Plastic Mach

Stainless Steel Aluminum Induction Ceramic Heater Band Extruder Head Band Heater

Stainless Steel Shell 220v Dia90x120mm 1500w Extruder Ceramic Band Heater For Making Masking

Ceramic band Heater Ring Element with Stainless Steel Shell 220V 380V 400V High Power