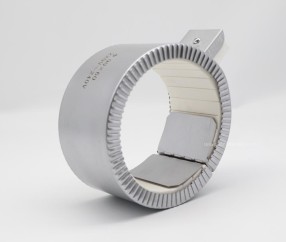

Stainless Steel Shell 220v Dia90x120mm 1500w Extruder Ceramic Band Heater For Making Masking

- Product Details

Key attributes

Product name: ceramic heating ring/Band Heater ElementsProduct features: uniform heating, high thermal efficiencyWhether to customize: Yes (customized power, voltage, outer diameter,inner diameter, height, wiring, etc.)

Scope of application: chemical industry, machinery, petroleum,shipbuilding, textile, metallurgy and other industries

1, heating ring size: inner diameter (mm)* height (mm)

2, voltage: such as: 380V, 240V, 230V, 220V, 110V,36V, 24V, 9V, etc.

3, power: We generally do in accordance with a square centimeter 3-5 watts, if there are special needs, please contact the seller

4, can open holes: square hole round hole

5, appearance: ceramic joints, high temperature line, screw outlet plug outlet line flexible and changeable

6, stainless steel heating plate is widely used in industrial equipment mold heating, chemical reagent heating and so on. Safe, stable and long life

Product name | Ceramic heating ring |

Normal temperature | 300-500℃ |

Voltage specification | 110V/220V/380V |

Product features | Rapid heating, high thermal efficiency |

Product power | Customized on demand |

Product specifications | Various specifications non-standard customization |

Product use | Widely used in injection molding machine, extruder, film blowing machine, cutting machine and so on |

Usage | 1, the working voltage shall not exceed 10% of the rated value 2, the wiring part should be placed outside the heating layer and insulation layer, the shell should be effectively grounded 3,should be stored in a dry place |

Applications of Ceramic band heaters :

1. Plastic Processing:

Injection Molding: Ceramic band heaters are used to heat the barrels of injection molding machines. They provide uniform temperature distribution, which is crucial for melting and molding plastic materials consistently.

Extrusion: In extrusion processes, these heaters are used to heat the barrels and nozzles of extrusion equipment. The even heat helps in maintaining the correct viscosity of the molten plastic.

2. Food Processing:

Cooking Equipment: In food processing, ceramic band heaters are used in machines such as ovens, fryers, and cooking vats to maintain precise temperatures.

Food Packaging: They are used in heat sealing machines for packaging food products, ensuring proper sealing and preservation.

3. Chemical Processing:

Reactors and Tanks: Ceramic band heaters can be used to heat reactors and tanks in chemical processing to ensure that reactions occur at the required temperatures.

Viscosity Control: Maintaining consistent temperatures helps in controlling the viscosity of chemical products.

4. Rubber and Polymer Processing:

Curing Ovens: Ceramic band heaters are used in curing ovens to maintain consistent temperatures during the vulcanization of rubber and other polymers.

Calenders: Used to heat rollers and calendering machines that shape and process rubber and plastic materials.

5. Metal Processing:

Heat Treatment: Used in heat treatment processes for metals, such as annealing or tempering, where precise temperature control is required.

Hot Runner Systems: In metal casting, ceramic band heaters are used to heat hot runner systems, which are integral to maintaining the temperature of molten metal.

6. Pharmaceuticals:

Equipment Heating: Used in pharmaceutical manufacturing equipment to maintain specific temperatures during the production of medications and other products.

Sterilization: Applied in sterilization processes where consistent heat is necessary to ensure the effectiveness of sterilization.

7. Laboratories:

Heating Elements: In laboratory setups, ceramic band heaters are used to heat test tubes, beakers, and other equipment where precise and stable temperatures are needed.

8. General Industrial Applications:

Temperature Maintenance: Any application requiring the maintenance of a specific temperature for equipment or processes can benefit from the use of ceramic band heaters.

Uniform Heating: Ideal for applications where even heat distribution is crucial to prevent hot spots and ensure consistent quality.

Over the years, we have worked hard to promote and realize the modernization of alloy sales, and actively cultivated and enhanced the ability of employees' independent innovation. All-round renovation and upgrade of the original business site, facilities and equipment, and modern computer management. Hope to establish long-term partnerships and win market reputation.

We are increasing thescale of trade and customers through out the world. With our good reputation we have won the trust of our customers. It's helps the modernisation of our country and promote the economic and technical exchanges with the rest of the world. We also look forward to enhance the friendship with other countries and make positive impact.

We warmly hope that you and us together, hand in hand, create a glorious future.

FAQ

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.

5000W Oil Heater Band Induction Ring Heating Element Ceramic Extruder Band Heater For Plastic Mach

Stainless Steel Aluminum Induction Ceramic Heater Band Extruder Head Band Heater

OEM Factory Barrel Ceramic Band Heater Infrared Ceramic Drums Plastic Extruder Band Heater For Heat

Ceramic band Heater Ring Element with Stainless Steel Shell 220V 380V 400V High Power