Ceramic band Heater Ring Element with Stainless Steel Shell 220V 380V 400V High Power

- Product Details

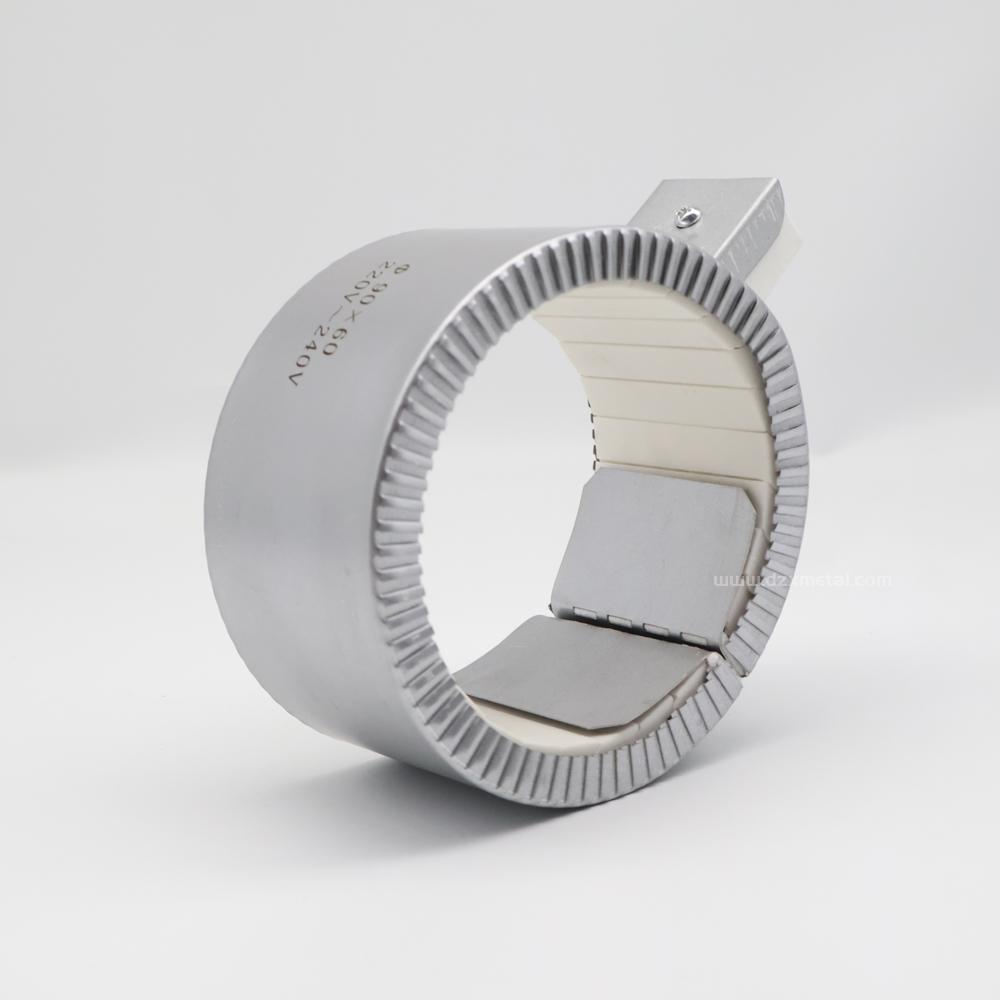

Ceramic Band Heater Ring

ceramic band heater ring is a specialized heating element designed for industrial applications. It combines the properties of ceramic materials with heating technology to provide efficient and uniform heat.

A ceramic band heater ring is a cylindrical heating device made from ceramic materials. It features embedded electrical heating elements and is designed to fit around cylindrical objects. Its primary function is to provide consistent and precise heating in various industrial processes.

Key Components of Ceramic Band Heater Ring:

Ceramic Core:

Material: Made from ceramic materials like alumina or other high-temperature ceramics.

Function: Provides excellent thermal insulation and electrical insulation, ensuring efficient heat transfer and preventing heat loss.

Heating Elements:

Material: Typically made from resistive alloys such as nickel-chromium (nichrome).

Function: Generates heat when an electrical current passes through them.

Metallic Sheath (Optional):

Material: Often made from stainless steel or other metals.

Function: Protects the ceramic core and heating elements, and may aid in mounting the heater ring to the target object.

Mounting Mechanism:

Clamps or Bolts: Used to secure the heater ring around the cylindrical object to ensure a tight fit and effective heat transfer.

Ceramic Band Heater Ring Details:

Applications of Ceramic Band Heater Ring

Ceramic band heater rings are versatile and used of industrial applications such as Plastic Extrusion and Injection Molding.

Plastic Extrusion:

Barrel Heating:

Purpose: Ceramic band heaters wrap around the extrusion barrel to heat the plastic material as it is fed through the barrel.

Function: They ensure uniform heating along the length of the barrel, which is essential for melting the plastic evenly and achieving consistent material flow.

Nozzle Heating:

Purpose: Applied to the nozzle of the extrusion machine to maintain the correct temperature for the plastic as it exits the machine.

Function: They prevent the plastic from solidifying prematurely and ensure smooth, accurate extrusion.

Temperature Control:

Purpose: Maintains precise temperature profiles to match different plastic types and processing conditions.

Function: Ceramic band heaters provide consistent temperature control, improving the quality and consistency of the extruded plastic products.

Injection Molding:

Mold Heating:

Purpose: Ceramic band heaters are used to heat the mold cavities in injection molding machines.

Function: They ensure the mold reaches and maintains the optimal temperature for proper plastic flow and solidification, leading to high-quality molded parts.

Temperature Uniformity:

Purpose: Achieves uniform temperature distribution across the mold surface.

Function: Consistent heating helps prevent defects such as warping or uneven cooling in the molded parts, improving the overall quality and dimensional accuracy.

Efficiency and Precision:

Purpose: Provides precise temperature control for different stages of the molding process.

Function: Enhanced temperature control improves cycle times and reduces waste, leading to more efficient production and lower costs.

Choosing the Right Ceramic Band Heater Ring:

Temperature Range:

Consideration: Ensure the heater can handle the required temperature for your specific application.

Size and Shape:

Consideration: Choose a heater that matches the dimensions of the cylindrical object it will be installed on for optimal fit and performance.

Power Requirements:

Consideration: Verify that the heater’s wattage and voltage specifications align with your system’s power supply.

Material Compatibility:

Consideration: Ensure the heater’s ceramic and metal components are compatible with the materials being processed and the operating environment.

Installation and Mounting:

Consideration: Check the mounting options (e.g., clamps, bolts) and ease of installation to ensure it fits your equipment setup.

About us:

Jiangsu DZX Technology Co,Ltd. is a professional engaged in the electric heater design, manufacture and sales of integrated entity enterprise, has over 20 years experience in electric heater of scientific research and production.

Our main product is heating resistance wire. heater elements and thermocouple series products

Enterprise has core technology advantage and introduce advanced technology and management concept, in accordance with the 1s09001 quality management requirements, strict control of raw materials quality,perfect detection means, with first-class technology,reliable quality and excellent service to win customers praise and praise.

5000W Oil Heater Band Induction Ring Heating Element Ceramic Extruder Band Heater For Plastic Mach

Stainless Steel Aluminum Induction Ceramic Heater Band Extruder Head Band Heater

Stainless Steel Shell 220v Dia90x120mm 1500w Extruder Ceramic Band Heater For Making Masking

OEM Factory Barrel Ceramic Band Heater Infrared Ceramic Drums Plastic Extruder Band Heater For Heat