220V Customized Electric Hot Runner Heater Brass Copper Extruder Coil Spring for Injection Machine

- Product Details

220V Electric Hot Runner Heater Brass Copper Extruder Coil for Injection Machine

Copper nozzle runner heater elements represent an advanced thermal engineering solution. These heaters are designed similarly to high watt density cartridge heaters and can be equipped with or without integrated Thermocouple s.

High Working Temperature: Capable of operating at elevated temperatures for demanding applications.

Fast Heating: Provides rapid heat-up times due to copper’s excellent thermal conductivity.

Uniform Heating Precision: Ensures consistent and even heating across the nozzle, which enhances process stability and product quality.

Long Service Life: Designed for durability and extended use, minimizing the need for frequent replacements.

Automatic Temperature Control: Can be integrated with temperature control systems for precise and automatic regulation.

High Thermal Conduction: Copper’s superior heat transfer capabilities ensure efficient and effective heating.

Reusability: While the internal heating material may wear over time, the external structure is built to be reusable, making it a cost-effective solution.

Name of product | copper hot runner nozzle heater |

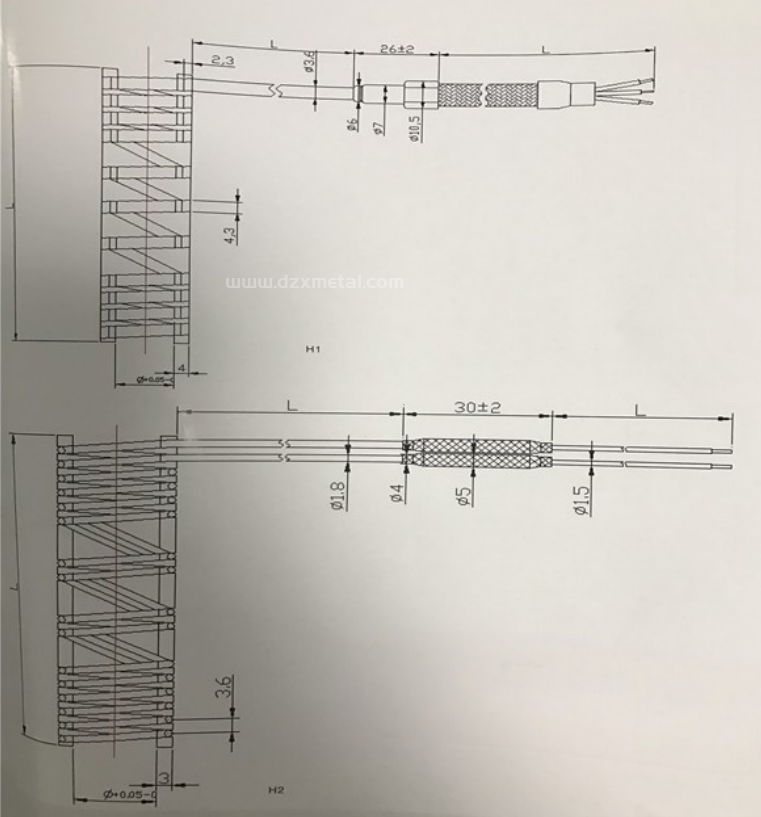

Inner Diameter of coiled heater | 8-100mm(+0.05mm) |

Coil style Length | 15-400mm(+0.05mm) |

Staright style length | 400-3000mm(0.5mm) |

Cross-section | Round Dia:1.8mm;3.7mm;4.2mm Rectangular:1.5×2.1mm;2.2×4.2mm;2.3×4.3;4×6mm; |

Tube Material | SUS304/SUS316 |

Power | According to your requirement |

Insulation | High purity MGO |

Inner heating element | NiCr8020 FeCrAl |

Voltage | 12v;24v;110v;220v;240v;380v |

Wattage | 100-1500W(5w/cm2) +5% -10% |

Max temperature | 650℃ |

Built-in thermocouple | With or without J/K TC(Available) |

Service | ODM/OEM |

Delivery time | 3-5 days (10-500pcs) |

Features of Copper Hot Runner Nozzle Heaters

Superior Thermal Conductivity:

Copper: With thermal conductivity around 400 W/m·K, copper ensures rapid and uniform heat distribution. This leads to quicker heating times and efficient energy use.

High Working Temperature:

Operating Range: Typically designed to handle temperatures up to 400°C (752°F) or more, depending on the specific design and insulation used. This makes them suitable for high-temperature molding applications.

Fast Heating:

Heat-Up Time: Due to copper's excellent heat conduction, these heaters achieve desired temperatures quickly, reducing cycle times and improving productivity in manufacturing processes.

Uniform Heating:

Temperature Consistency: Ensures even heat across the nozzle, which is crucial for preventing issues such as cold spots and ensuring consistent melt quality in plastic injection molding.

Precision Control:

Thermocouples: Can be integrated with K-type or J-type thermocouples for precise temperature monitoring and control. This allows for accurate adjustments and stable operating conditions.

Durability:

Long-Lasting: Built to withstand the harsh conditions of high-temperature operations, with resistance to thermal cycling and mechanical stress, ensuring a long service life.

High Watt Density:

Compact Efficiency: Designed to deliver high power output in a small footprint. This allows for effective heating in tight spaces and provides intense localized heat.

Reusability:

External Structure: The external casing and mounting hardware are designed for reuse. Only the internal heating elements may need replacement, which lowers overall maintenance costs.

Customizable Design:

Variety of Configurations: Available in different diameters, lengths, and shapes to fit specific nozzle designs and application needs. Custom designs can be provided for unique requirements.

Energy Efficiency:

Effective Heat Transfer: Minimizes energy loss by focusing heat directly where it is needed, reducing overall energy consumption and operating costs.

Insulation Options:

Thermal Insulation: Often comes with high-quality insulation materials to prevent heat loss and protect surrounding components from excessive temperatures.

Ease of Installation:

User-Friendly: Designed for straightforward installation with clear mounting instructions. Many models include features for easy integration into existing systems.

Maintenance:

Low Maintenance: Requires minimal upkeep, with periodic checks needed mainly for the internal heating elements. The robust design helps in reducing the frequency of replacements.

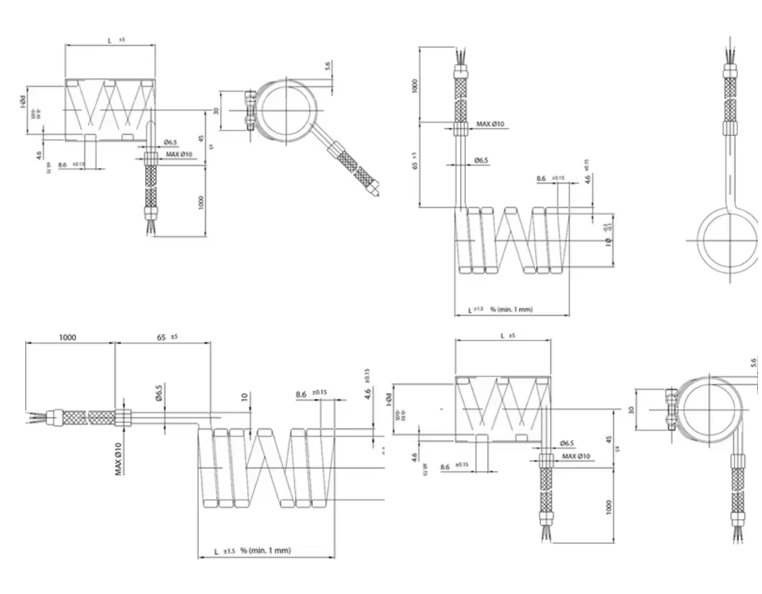

Size of Copper Hot Runner Nozzle Heaters

Application of Copper Hot Runner Nozzle Heaters

Injection Molding

Precision Temperature Control: Ensures consistent melt temperatures, reducing defects and improving part quality.

Improved Cycle Times: Rapid heating and uniform temperature distribution lead to faster production cycles.

Enhanced Mold Performance: Maintains stable mold temperatures for better dimensional accuracy and fewer defects.

Energy Efficiency: Efficient heat transfer reduces energy consumption and operating costs.

Quick Heat-Up Times: Shortens startup times, allowing for faster readiness and increased productivity.

Plastic Extrusion

Consistent Temperature Control:Benefit: Maintains stable melt temperatures for uniform material flow and quality.

Improved Processing Efficiency:Quick and efficient heating reduces cycle times and increases throughput.

Blow Molding

Precise Temperature Management:Ensures consistent wall thickness and high-quality finishes in blow-molded products.

Efficient Heat-Up:Reduces startup times and enhances overall production efficiency.

Die Casting:

Purpose: Helps maintain accurate temperatures in die-casting molds, which is essential for producing high-quality metal castings.

Example: Used for components in the automotive and aerospace industries.

General Industrial Heating:

Purpose: Suitable for any application requiring efficient and uniform heating.

Example: Applied in various manufacturing processes where precise temperature control is needed.

FAQ for Copper Hot Runner Nozzle Heaters

1. What are these heaters used for?

They provide precise heating in injection molding, plastic extrusion, and blow molding.

2. Why is copper used?

Copper offers excellent thermal conductivity for rapid and uniform heating.

3. Can they handle high temperatures?

Yes, they typically operate up to 400°C (752°F).

4. Are thermocouples included?

They can be, for accurate temperature control.

5. How do I maintain these heaters?

Regularly inspect and clean, and check connections for wear or damage.

6. What if the heater isn’t working?

Check connections and consult the manual or support team if issues persist.

Factory Direct 300W 500W J K Type Thermocouple Electric Spring Hot Runner Coil Heater

Electric Spring Coil Hot Runner Stainless Steel Nozzle Heater With J Type Thermocouple

230V 500W Hot Runner Mould Industrial Heater Injection Molding Machine Spring Heater

Stainless Steel Round and Flat Heating Tube Hot Runner Coil Heater Element with K Type Thermocouple