230V 500W Hot Runner Mould Industrial Heater Injection Molding Machine Spring Heater

- Product Details

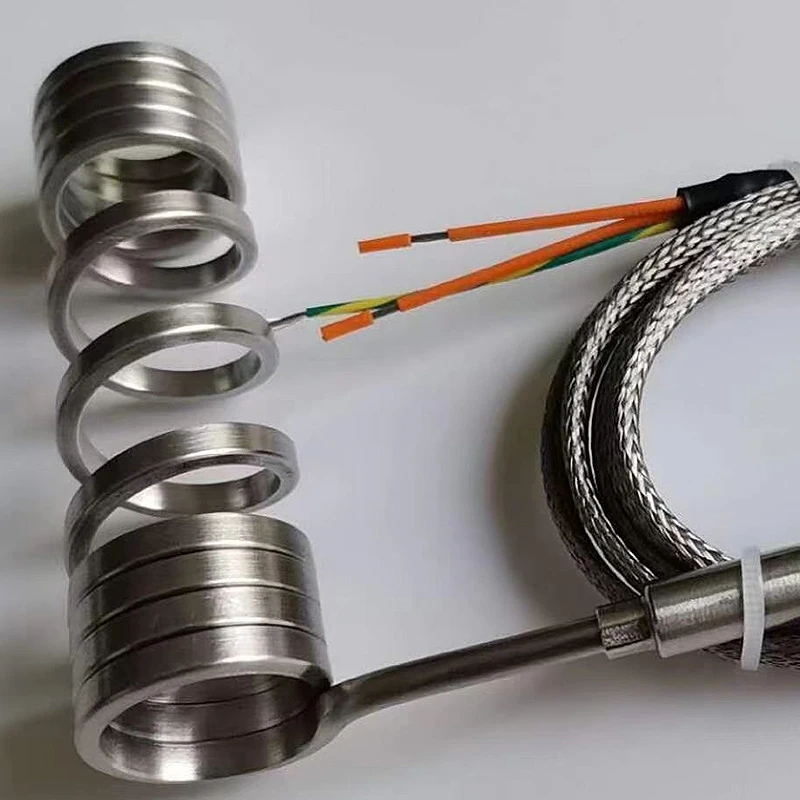

industrial high temperature electric spring nozzle brass Hot Runner coil copper heater

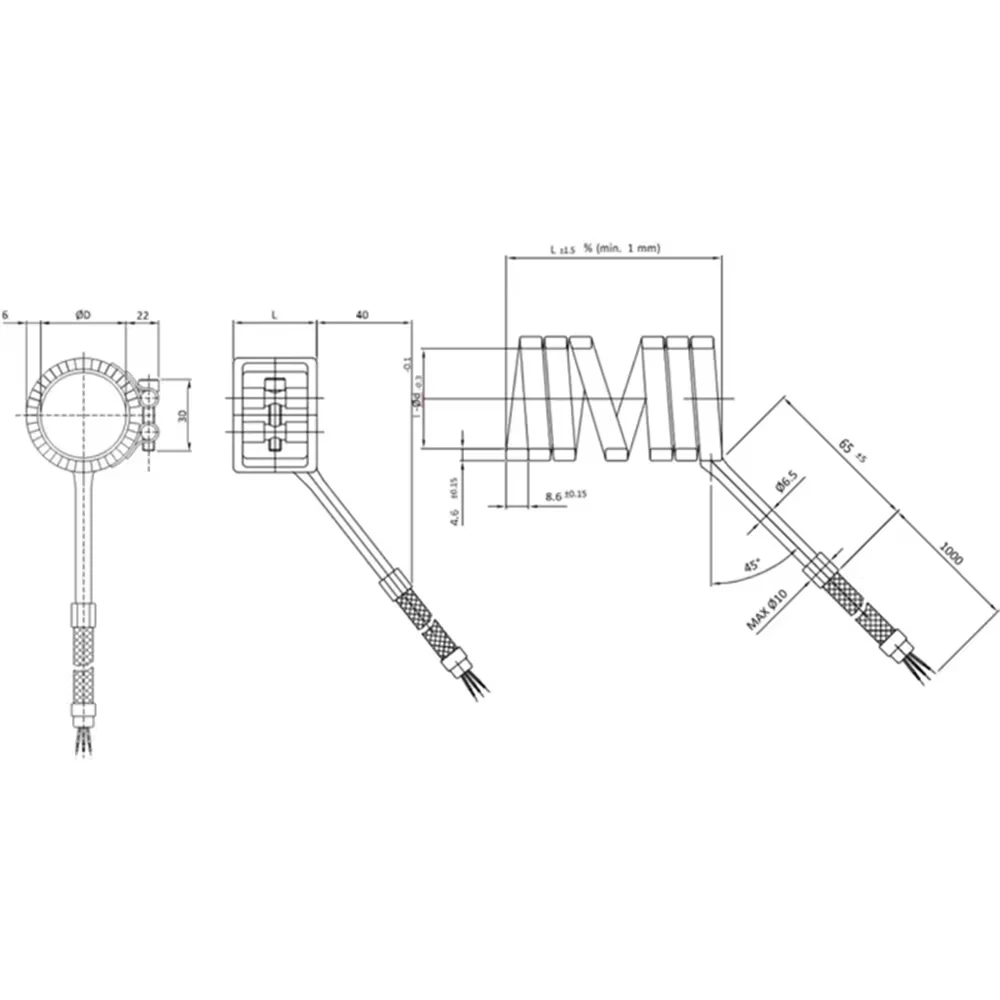

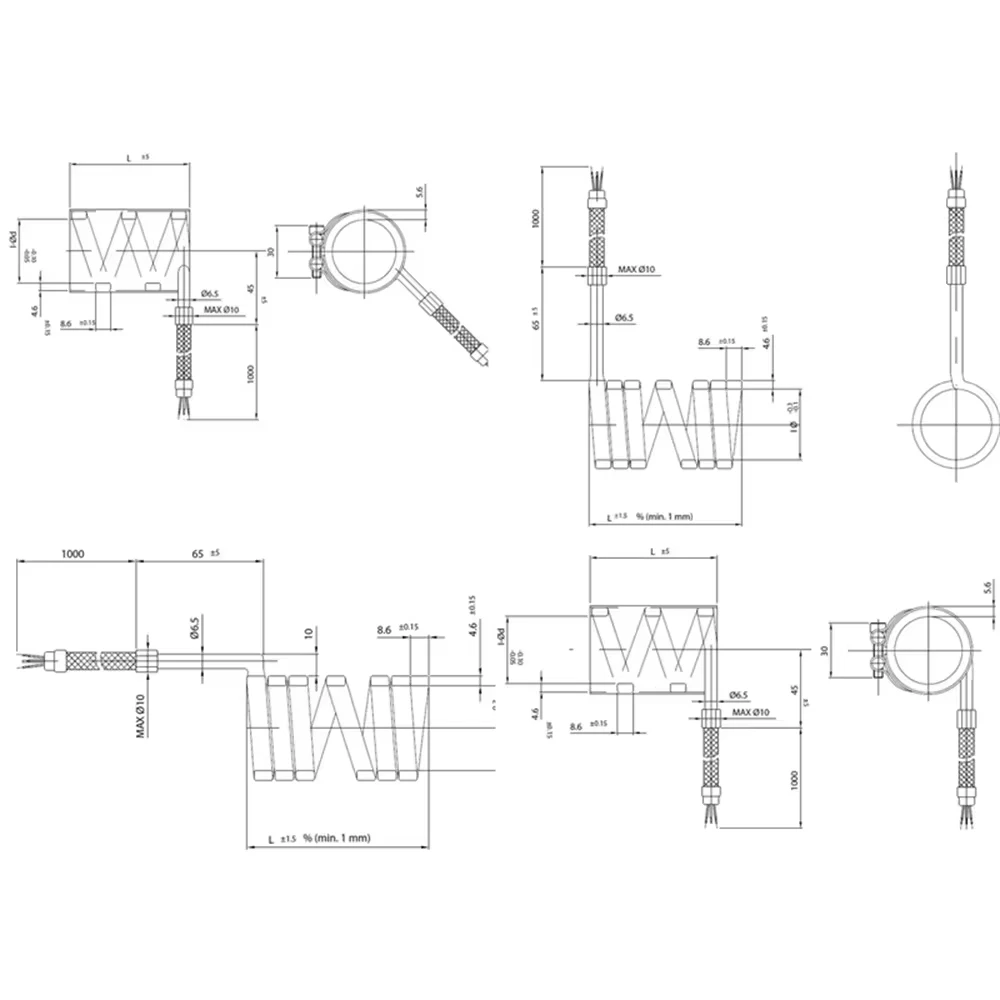

The Hot Runner Heater, measuring 30*250mm, is engineered for precision heating in injection molding applications. Constructed from nickel-chrome resistance wire encased in a durable chrome-nickel steel tube, it features magnesium oxide (MgO) insulation to optimize heat transfer. These heaters undergo an annealing process, allowing them to be easily bent into various custom configurations. Models equipped with built-in thermocouples are also available.

Coil heaters, or cable heaters, can be shaped to suit a wide range of applications. Typically designed as compact, high-efficiency nozzle heaters, they are fully annealed for peak performance.

These coil heaters are essential for injection molding machine nozzles and sprue bushings, providing comprehensive 360° heat coverage. They also come in options with distributed wattage to meet specific heating demands.

Moreover, coil heaters are adaptable as cartridge heaters for uniquely sized openings. A straight, round cable heater can seamlessly fit through a sealing bar in packaging machinery.

Sheath Material | ss304ss321ss316 |

Heating conductor compound | NiCr8020 |

Maximum Sheath Temperature | 750°C |

High voltage strength(cold) | 800V-AC |

Voltage | AC220V~240V |

Power tolerance(cold) | ±0.05 |

Length Tolerance (Straight) | ±5% |

Insulation resistance(cold) an1000V-DC | ≥100MΩ |

Leakage current(cold) | 600V≤0.5MA |

Max.surface load on heater sheath | 10W/cm |

Miimum bending fadius(internal) heated | 3mm |

and unheated zone |

Description of Coil Heater:

1) Spring coil heater is made of nickel chrome resistance wire placed inside chrome nickel steel tube that is filled with MgO powder.

2) Spring coil heater is also known as high performance tubular heaters or cable heaters.

3) Spring heater can be produced with or without built in thermocouples.

3) Spring coil heater is widely used in heating engineering, mold, plastic industry, including the transfer machinery, medical equipment, casting process, welding, heat treatment process and many other industries and fields

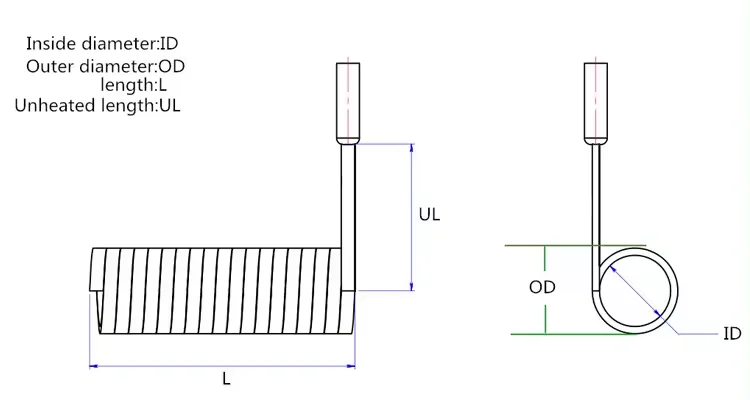

Specification

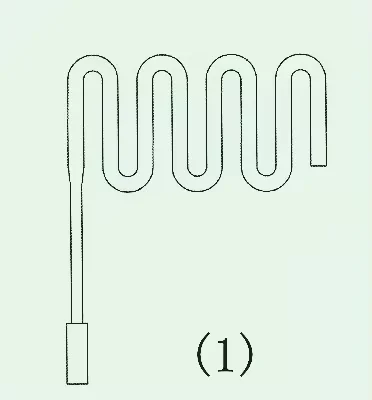

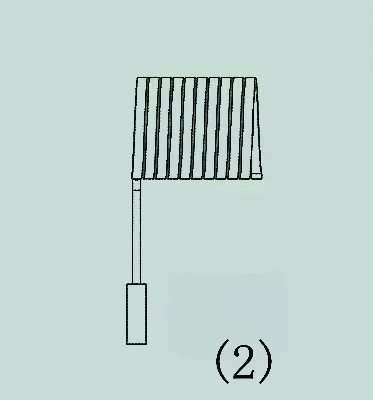

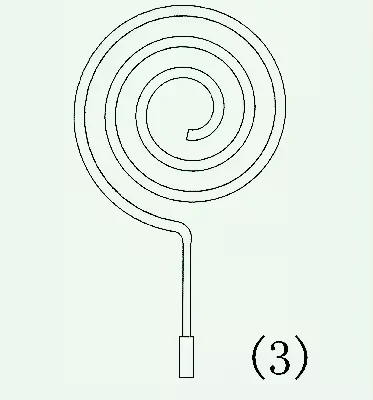

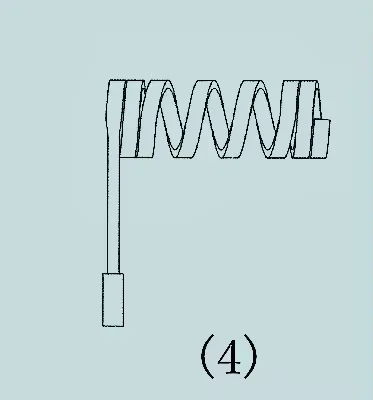

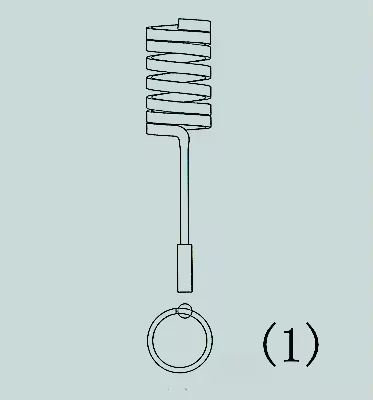

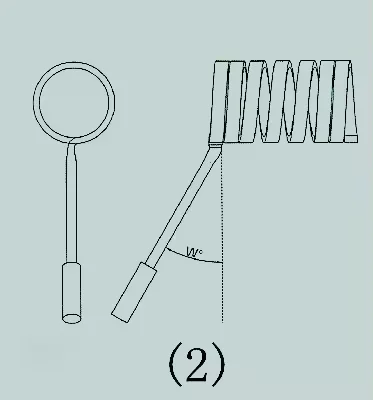

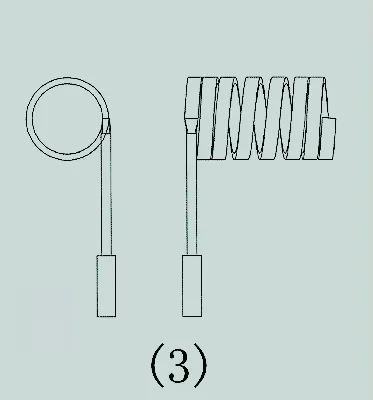

Coiling schemes

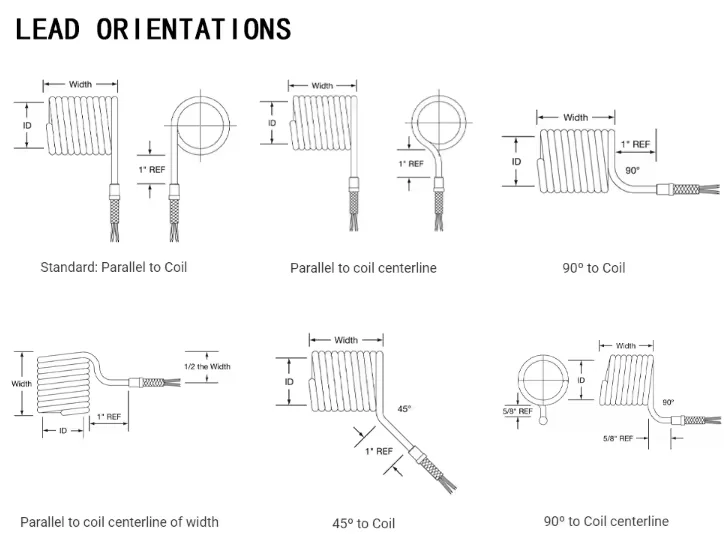

Coil exits

Our Advantages

1 We use German Nichrome high quality heating wire to improve heating effect and service life

2 We use imported high-purity Mgo rods, which have good thermal conductivity, are not easy to get wet, have high density, can better

3 The heater is uniformly heated as a whole, which can uniformly heat the mold nozzle, make the mold sol smoother, effectively improve production efficiency, and reduce the difficulty of adjusting the parameters of the injection molding machine caused by unstable heating. wrap the heating wire, and are less prone to break the metal shell.

4 The lead part adopts imported high temperature resistant wires to reduce the short circuit of the heater caused by the damaged wire sheath.

Over the years, we have worked hard to promote and realize the modernization of alloy sales, and actively cultivated and enhanced the ability of employees' independent innovation. All-round renovation and upgrade of the original business site, facilities and equipment, and modern computer management. Hope to establish long-term partnerships and win market reputation.

We are increasing thescale of trade and customers through out the world. With our good reputation we have won the trust of our customers. It's helps the modernisation of our country and promote the economic and technical exchanges with the rest of the world. We also look forward to enhance the friendship with other countries and make positive impact.

We warmly hope that you and us together, hand in hand, create a glorious future.

FAQ

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.

Factory Direct 300W 500W J K Type Thermocouple Electric Spring Hot Runner Coil Heater

Electric Spring Coil Hot Runner Stainless Steel Nozzle Heater With J Type Thermocouple

220V Customized Electric Hot Runner Heater Brass Copper Extruder Coil Spring for Injection Machine

Stainless Steel Round and Flat Heating Tube Hot Runner Coil Heater Element with K Type Thermocouple