500W Hot Runner Heater With Thermocouple K J Wire for Injection Molding

- Product Details

Hot Runner Heater

Hot runner heater is used in injection molding to keep the molten plastic at a consistent temperature as it flows through the runner system. It ensures uniform heat distribution to prevent cooling and solidification before the material reaches the mold cavity. These heaters are critical for maintaining the quality and efficiency of the molding process.

Applications Hot Runner Heater:

Automotive Parts:

Components: Dashboard panels, trim pieces, and housings.

Benefits: Consistent temperature helps in achieving high-quality, defect-free parts with minimal waste.

Consumer Electronics:

Components: Enclosures, connectors, and internal parts of devices like smartphones and tablets.

Benefits: Precision heating ensures tight tolerances and smooth surfaces, which are critical for electronics.

Packaging:

Components: Caps, closures, and containers.

Benefits: Reliable heating leads to uniform product quality and reduced cycle times, which are important for high-volume production.

Medical Devices:

Components: Syringes, housings, and various small intricate parts.

Benefits: Precision in temperature control is crucial for maintaining the integrity and functionality of medical components.

Consumer Goods:

Components: Toys, household items, and kitchenware.

Benefits: Hot runner systems help in producing aesthetically pleasing and durable products with consistent quality.

Industrial Components:

Components: Machinery parts, tools, and fittings.

Benefits: Ensures consistent quality and performance, which is essential for reliability in industrial applications.

Large Parts:

Components: Automotive bumpers, large housings, and panels.

Benefits: Hot runner systems facilitate the production of large parts by maintaining a consistent flow and temperature throughout the mold.

Complex Geometries:

Components: Parts with intricate designs or multiple features.

Benefits: Effective temperature control helps in achieving detailed and accurate shapes without defects.

Material Composition and Selection for Hot Runner Heaters:

1. Nickel-Chromium (NiCr) Alloys

Composition: Typically contains 80% nickel and 20% chromium.

Selection: Ideal for heating elements due to their high melting point, resistance to oxidation, and excellent electrical conductivity.

2. Stainless Steel

Composition: Mainly iron, with 10-20% chromium, and often nickel and molybdenum.

Selection: Used for structural parts and housings; provides good resistance to corrosion and high temperatures.

3. Ceramic Materials

Composition: Includes materials like alumina (Al2O3) or silicon carbide (SiC).

Selection: Chosen for high-temperature resistance and thermal insulation; often used in heaters that need to withstand very high temperatures.

4. Copper

Composition: Pure copper or copper alloys.

Selection: Used where high thermal conductivity is needed, though less common for direct heating elements due to its lower melting point compared to other materials.

5. Silicone Rubber

Composition: Silicone polymers with fillers to enhance thermal conductivity.

Selection: Suitable for flexible heaters and insulation; offers high flexibility and good resistance to temperature extremes.

6. Molybdenum Disilicide (MoSi2)

Composition: Composed of molybdenum and silicon.

Selection: Used in extreme temperature applications; provides high-temperature stability and resistance to oxidation.

7. Alumina (Aluminum Oxide)

Composition: Pure aluminum oxide.

Selection: Ideal for high-temperature insulation; offers excellent thermal and electrical insulation properties.

Hot Runner Heaters Factors in Material Selection:

Temperature Range: Ensure the material can withstand the operating temperatures without degrading.

Thermal Conductivity: Materials with high thermal conductivity ensure efficient heat distribution.

Corrosion and Oxidation Resistance: Materials must resist environmental factors that can cause degradation.

Mechanical Properties: Consider the material's strength and durability under operating conditions.

Cost and Availability: Balance performance requirements with budget constraints and material availability.

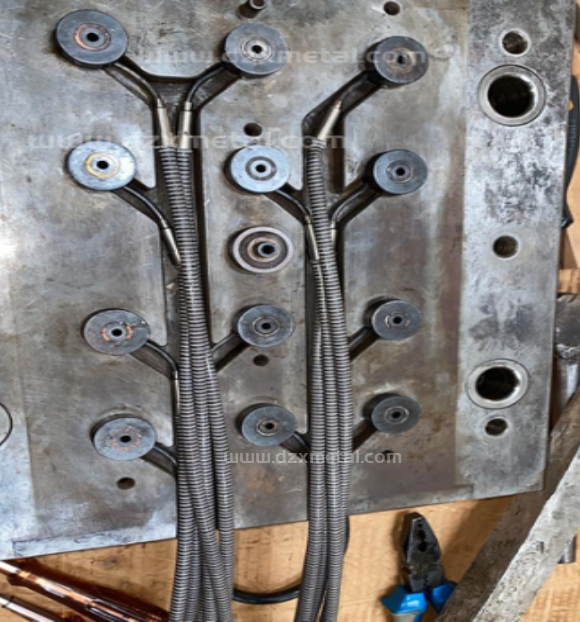

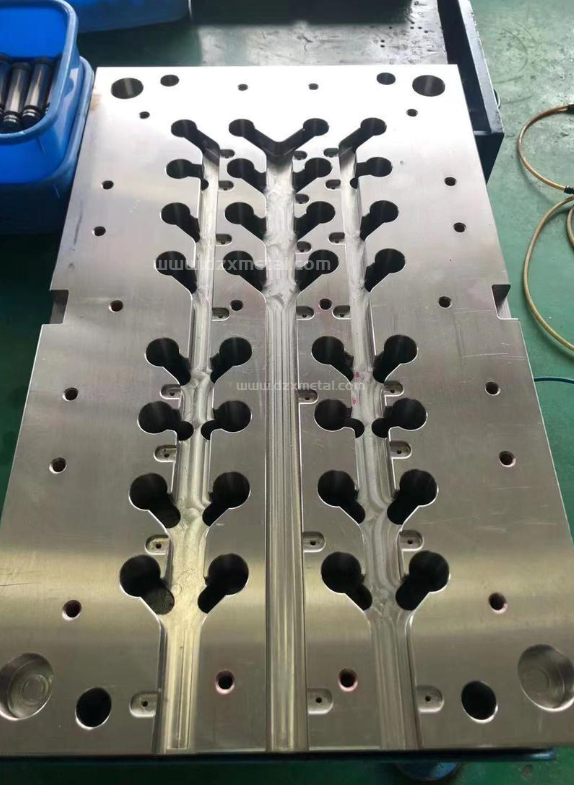

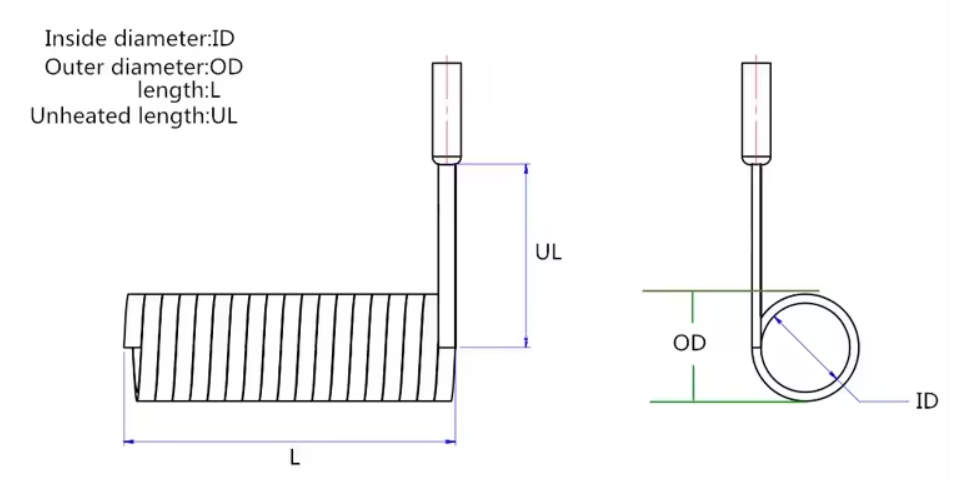

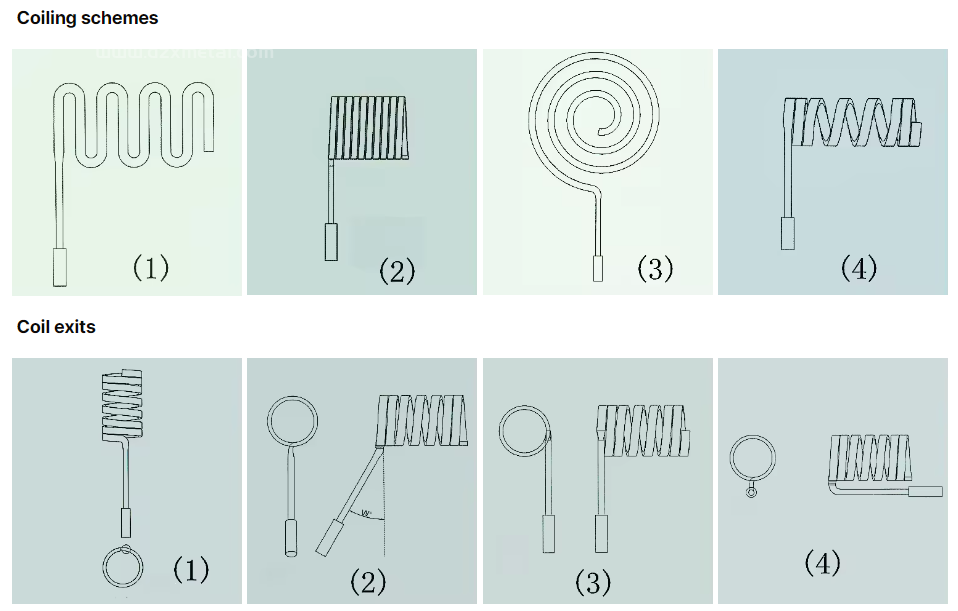

Size Confrim about Hot Runner Heaters:

About Company:

Factory Direct 300W 500W J K Type Thermocouple Electric Spring Hot Runner Coil Heater

Electric Spring Coil Hot Runner Stainless Steel Nozzle Heater With J Type Thermocouple

230V 500W Hot Runner Mould Industrial Heater Injection Molding Machine Spring Heater

220V Customized Electric Hot Runner Heater Brass Copper Extruder Coil Spring for Injection Machine