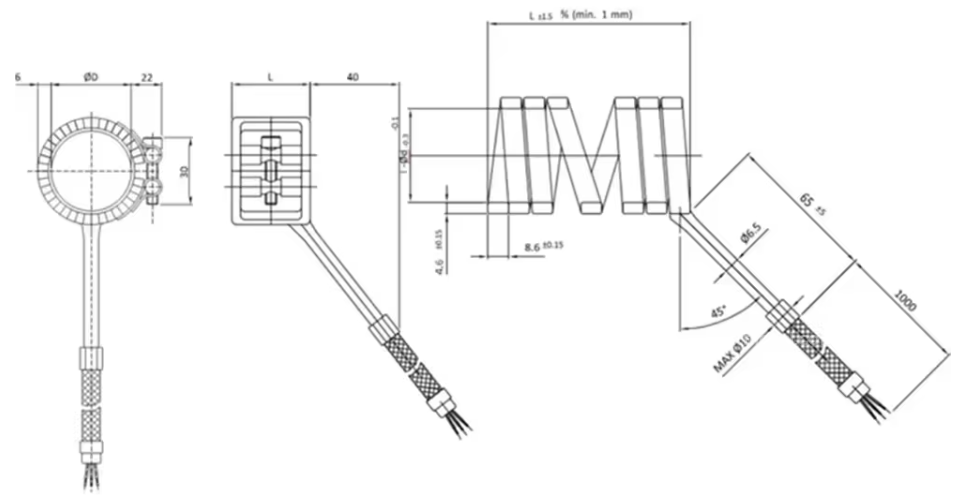

Hot runner heaters 220V Stainless Steel Flexible Coil Heater Element with J Type 5 Wire Thermocouple

- Product Details

Hot runner heaters

Hot runner heaters are critical components in injection molding systems. They’re designed to keep the plastic in the runner system of an injection mold at a consistent, optimal temperature.

Purpose: The main goal of hot runner heaters is to maintain the molten plastic in a fluid state so it can flow easily through the runner system and into the mold cavities. This helps in reducing cycle times, improving the quality of the molded parts, and minimizing waste.

Types:

Band Heaters: These wrap around the runner and nozzle components to provide uniform heating.

Cartridge Heater s: Inserted into the mold or runner block, these heaters provide localized heat.

Nozzle Heaters: Specifically designed to heat the nozzles where the plastic is injected.

Control: Precise temperature control is essential. Hot runner systems typically use thermocouples or RTDs (Resistance Temperature Detectors) to monitor the temperature and feedback to the heating controls to maintain consistency.

Maintenance: Regular maintenance is crucial for hot runner heaters to ensure they operate efficiently. This includes checking for wear and tear, ensuring proper insulation, and calibrating temperature sensors.

Benefits: Effective hot runner systems improve the quality of molded parts by reducing issues like cold spots, weld lines, or inconsistent filling. They also enhance efficiency by shortening cycle times and reducing energy consumption.

| Sheath Material | ss30 4ss321 ss316 Copper |

| Heating conductor compound | NiCr8020 |

| Maximum Sheath Temperature | 750℃ |

| Voltage | AC220V~380V |

| Power tolerance(cold) | ±0.05 |

| Length Tolerance (Straight) | ±5% |

| Insulation resistance(cold) an1000V-DC | ≥100MΩ |

| Leakage current(cold) | 600V≤0.5MA |

| Max.surface load on heater sheath | 10W/cm |

| Miimum bending fadius(internal) heated | 3mm |

Advantage of hot runner heater

1. Improved Product Quality

Consistent Temperature: Hot runner heaters maintain a uniform temperature throughout the runner system, reducing temperature variations that can cause defects like short shots, sink marks, or weld lines.

Reduced Cooling Time: By keeping the plastic molten and evenly heated, hot runner systems can help produce parts with smoother surfaces and more precise details.

2. Enhanced Efficiency

Reduced Cycle Times: Consistent heating allows for quicker cooling and solidification of the plastic, which shortens the overall cycle time and increases production speed.

Lower Energy Consumption: Efficient temperature control minimizes energy waste, as the system only uses the amount of heat necessary to maintain optimal conditions.

3. Minimized Waste

Less Scrap: By maintaining the plastic in a fluid state, hot runner systems reduce the amount of plastic that solidifies in the runner system, which is often discarded in cold runner systems.

Fewer Quality Issues: Better temperature control reduces the likelihood of defects that can lead to scrapped parts.

4. Reduced Labor and Maintenance Costs

Fewer Adjustments: With precise and stable temperature control, the need for manual adjustments and monitoring is reduced.

Lower Maintenance: Hot runner systems generally require less frequent maintenance compared to cold runner systems, as there are fewer issues related to material solidification and blockages.

5. Greater Design Flexibility

Complex Parts: Hot runner systems can efficiently produce complex parts with intricate geometries, as they can maintain consistent heating even in areas with complex flow paths.

Multiple Cavities: They are well-suited for multi-cavity molds, allowing for efficient production of many parts simultaneously.

6. Reduced Material Costs

No Runner Waste: Since the runner system remains molten and reusable, there's no need to discard or recycle runner material, which lowers overall material costs.

Optimized Material Use: Hot runner systems can precisely control the amount of material used, leading to better material utilization.

7. Faster Startup and Changeover

Quick Warm-Up: Hot runner systems heat up faster than cold runner systems, reducing the time required to start up a mold and begin production.

Efficient Color Changes: When switching colors, hot runner systems allow for faster and more efficient purging and color changes.

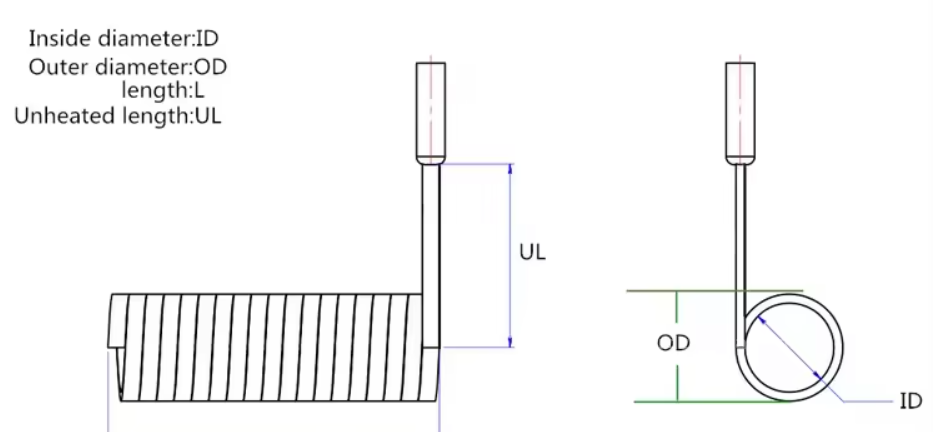

Selecting the right size for a hot runner coil heater:

1. Heat Output Requirement

Calculation: Determine the required wattage based on the mold’s size, the type of plastic being used, and the desired temperature. This often involves calculating the heat needed to maintain the molten state of the plastic and compensate for heat losses.

Factory Direct 300W 500W J K Type Thermocouple Electric Spring Hot Runner Coil Heater

Electric Spring Coil Hot Runner Stainless Steel Nozzle Heater With J Type Thermocouple

230V 500W Hot Runner Mould Industrial Heater Injection Molding Machine Spring Heater

220V Customized Electric Hot Runner Heater Brass Copper Extruder Coil Spring for Injection Machine